Food Dehydration Technology

Dedicated April 18, 2007, at the United States Department of Agriculture’s ARS Eastern Regional Research Center in Wyndmoor, Pennsylvania.

Instant mashed potatoes are commonplace on grocery shelves and have found wide use institutionally and in domestic and international food aid programs. The most successful form of instant mashed potatoes resulted from the flake process developed in the 1950s and 1960s at the Eastern Regional Research Center, a United States Department of Agriculture facility outside of Philadelphia. The process for reconstituting instant mashed potatoes devised at this facility utilized dehydration technology. Subsequent research at the ERRC led to the introduction of other high-quality dehydrated vegetable products, many of these the result of research in explosion-puffing processes.

Contents

- The U.S. Department of Agriculture and Utilization Research

- History of Dehydrated Potatoes

- Potato Dehydration Research at the Eastern Regional Research Center

- Instant Potatoes and other Dehydrated Potato Products

- Drying Fruits and Vegetables: The Explosion-Puffing Process

- Research Notes and Further Reading

- Landmark Designation and Acknowledgments

- Cite this Page

The U.S. Department of Agriculture and Utilization Research

The 1950s were a decade "between" for women: Between the war years that forced millions into the workplace—symbolized by Rosie the Riveter—and the rise of feminism in the 1960s. In between, in the silent 50s, television conveyed the dominant image of women as homemakers in such shows as The Donna Reed Show and The Loretta Young Show. Still, the TV image of the role of women is only half the story. Many women worked out of need; for others, rising affluence and leisure freed them from household chores. In either case, women sought labor-saving devices: machines to ease drudgery and new products to simplify life. Convenience foods—aimed at making food preparation easy and quick—became commonplace.1

The interest in convenience foods merged with a change in eating habits as rising incomes meant consumers could afford more expensive foods, such as meats and fresh leafy green vegetables. This threatened many old staples of the American diet such as the potato, worsening the chronic problem of overproduction. Indeed, by the middle of the 20th century potato growers—especially in the eastern United States—suffered crop surpluses and lower prices. At the same time as demand diminished, production increased even as farmers planted fewer and fewer acres of potatoes. The reduction in acreage devoted to potato growing was more than offset by a phenomenal rise in yields per acre, from 122 bushels in 1939 to 250 by 1955.2

Potatoes were hardly the only U.S. crop plagued by overproduction as mechanization and newer and better crop varieties resulted in farmers producing more on less land. The inflation of the 1920s led to higher costs for consumer goods at a time when the prices farmers could charge for their goods were declining. The Great Depression followed, a deflationary era which drove commodity prices even lower, forcing many off the land and impoverishing those who remained. Congress responded to the crisis of American agriculture with the 1938 Agricultural Adjustment Act which set up four United States Department of Agriculture regional research laboratories. Each center was to be in a major farm producing area and each was charged with finding new markets and uses for regional farm commodities.3

Philadelphia was chosen as the site for the Eastern Regional Research Center (ERRC), originally named the Eastern Utilization Research and Development Division.4 The commodities traditionally assigned to it included fruits, vegetables, meat, dairy products, animal fats, and tanning materials. Much of the chemical engineering work at the ERRC has focused on developing processes to finding ways to converting perishable commodities into stable and convenient forms.5 By the 1950s a multidisciplinary team of chemists, chemical engineers, and food technologists at the ERRC zeroed in on the potato, attempting to reverse the decline in U.S. potato consumption.

I was peeling potatoes in my sleep.”

— John Sullivan, ERRC chemical engineer

History of Dehydrated Potatoes

Convenience foods became increasingly important in the years after World War II as busy lives meant less time for food preparation. Fresh fruits and vegetables were available only seasonally. Frozen foods were entering the market in the 1940s and 1950s. Dehydrated products were available, but they suffered from lengthy preparation times (hardly making them "convenient"), flavor deficiencies, and difficulty in re-hydration.6

In the summer of 1953 research began on the potato flake process at the Eastern Regional Research Center.7 This facility was particularly interested in finding in new methods for processing potatoes that would allow for the use of potatoes with a relatively low solid content, varieties of which were common in the eastern United States. Previously, Idaho Russet Burbanks were used commercially in making dehydrated mashed potatoes because of their high solid content, necessary to obtain good texture when reconstituted.8

Processing potatoes for storage has a long history; the Incas used climate to produce the first dehydrated potatoes. The process entailed an overnight freezing and thawing cycle plus low humidity. The ice crystals that formed forced openings in the cell tissue allowing for liquid to escape. The Incas employed foot power to expel the liquid. The cycle was repeated several times to lower the moisture content and then the marble-sized potatoes were dried for storage. The Incas called it Chuno, and it was a staple used by soldiers; sufficient quantities were dehydrated as well to guard against shortages.9

Europeans first used potatoes for provisioning ships in the 16th century. Then they were introduced into Europe and by the 18th century the potato had become the major food source in a large part of the continent. But the potato had two major drawbacks: it was bulky, and it had a relatively short shelf life, at least in comparison to grains. Experiments began in the late 18th century to solve this problem, in part to make the potato more useful as a foodstuff aboard ships. Potato flour was prepared in 1786 and experiments were conducted to find processes for drying potatoes.10 In the end, potato flour and potato starch—first produced in the United States in 1831—were the main examples of potato processing. 11

Potato chips—first called Saratoga chips—appeared in the middle of the 19th century. At first, chips were prepared in the home, accompanied by some small-scale commercial production. Major commercial applications had to await improved peeling and frying techniques. Potato chip production did not become a big business until after World War II.12

Potato Dehydration Research at the Eastern Regional Research Center

The drop in potato consumption in the middle of the last century coupled with increased consumer demand for convenience foods prompted a renewed search for ways of extending the shelf life of potatoes, with emphasis on developing instant mashed potatoes. Ultimately, two processes emerged for producing dehydrated mashed potatoes: granules and flakes. The USDA's Western Regional Research Center focused on developing a potato granule process. Granules were introduced as a home product in the late 1940s and the military showed interest during the Korean War. Granules were best suited to institutional markets; by the 1970s production of granules declined due to decreasing purchases by the military. While granules have a long shelf life, they do not re-hydrate quickly, limiting their usefulness as a convenience food.13

Potato flakes replaced granules as the leading form of dried mashed potatoes.14 The flake process as developed at the ERRC had the inherent advantages of being easily controlled, and it used familiar drying equipment. Appearance and flavor quality were high because the entire dehydration process takes less than half a minute. A short drying process imparts a baked potato flavor to the instant mashed potatoes.15

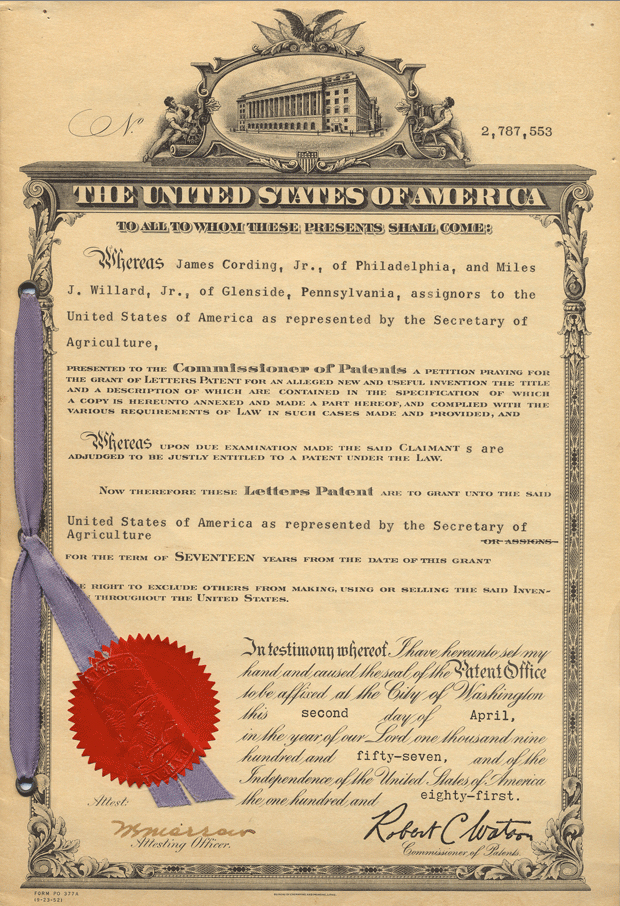

Initial research at the ERRC was conducted under Laboratory Chief Roderick K. Eskew and two chemical engineers, James Cording and Miles J. Willard. In their initial research, Cording and Willard devised a patent to make flakes on a tiny double-drum drier that dried the potatoes in about twenty seconds from 80% moisture to 5%. Speed of drying was the key; earlier drum-dried potatoes were used for paste as they were not edible. Quick drying eliminated the problem of cell rupture—causing a pasty product—which had plagued earlier attempts at instant mashed potatoes.16 Eventually, Cording and Willard, joined in 1954 by John Sullivan, concluded that a single-drum drier was preferable as it yielded a denser flake that was less costly to package.17

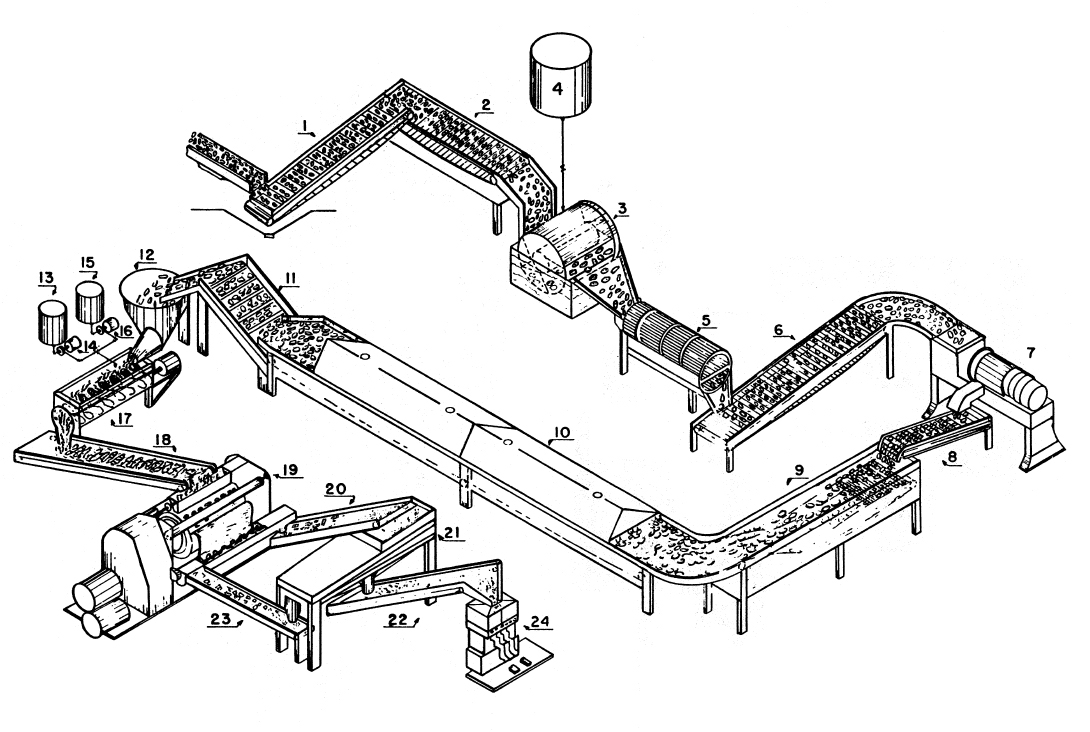

Fixing on a quick drying process using a single-drum drier was a major research breakthrough. Ensuing research focused on the appearance and flavor of the reconstituted flakes. In studies conducted in 1954 and 1955, the researchers found that the structure of the potato cell could best be maintained by utilizing what came to be known as the "Philadelphia cook," a three-step controlled cooking sequence.18

After the potatoes are peeled (treating with lye was determined to be the best method), trimmed, and sliced to about 5/8 inch thickness, the first cooking step occurs. This is a pre-cook at a relatively low temperature to prevent the cells from softening but one that was determined to be high enough to gelatinize the starch in the potatoes.19 The optimal temperature was determined to be between 150° F and 165° F for about twenty minutes. Cording in particular noted that at that temperature and time the cell structure remained intact.20 The initial pre-cook produces the potato slices that are no longer crisp but are tougher, resilient, and translucent. Potatoes pre-cooked the requisite temperature and amount of time remain firm, requiring additional steam cooking to soften them before mashing and dehydration. Because the starch has been gelatinized, the potatoes are not sticky when reconstituted; in fact, stopping the pre-cook at the point of gelatinization is critical for preserving the cell structure.21

After the pre-cook, the potatoes are then cooled to stop the cooking process and further harden the cells.22 Cooks have long known that cooling cooked, starchy vegetables in cold water reduces their stickiness. The USDA studies determined that the temperature of the cooling water and the length to time the pre-cooked potatoes needed to be cooled depended on the variety of cultivar used. In general, lower-solids potatoes needed longer cooling times.23

There are several types of steam cookers employed in the final cook, but whatever the method care must be taken to achieve the requisite separation of the potato cells with a minimum of rupture. Overcooking—resulting in such a rupture—leads to poor texture and flavor in the reconstituted mashed potatoes. Cooking time varies from fifteen minutes to one hour, depending on the solids content of the potato.24

Pastiness caused by cell rupture can also be mitigated if the potatoes are mashed immediately following the final cooking. Experiments at the ERRC determined that additives should be incorporated into the mash before drying to improve texture and extend shelf life. One common additive is a dilute solution of sodium bisulfite to retard non-enzymatic browning; another is a monoglyceride emulsifier which also contains antioxidants and which helps to avoid a pasty or rubbery texture.25

The final step in the production of the mashed potatoes is drying. Tests showed that a single-drum drier outfitted with four to six applicator rolls allowed for the production of potato flakes from lower solids type potatoes commonly grown on the East Coast. This is because the single-drum drier produces thicker and more uniform sheets than the double-drum version. In any event, moisture is reduced in the mash to about 6%.26

The processed potatoes come off the drum drier as a continuous sheet. The sheets must then be broken into flakes, a step in which free starch is released at the periphery of the flake. If the flakes are large the broken cells are insignificant; but as the flakes become smaller, the number of broken peripheral cells increases resulting in a difference in texture. Similarly, a high-density flake suffers less damage on breaking than one of low density.27

Instant Potatoes and other Dehydrated Potato Products

The potato flake process spawned a new industry and yielded a product with a stable shelf life that could be reconstituted into instant mashed potatoes with good texture, flavor, and aroma. Commercial applications of the potato flake process increased demand for potatoes. In addition, the use of the "Philadelphia cook" enabled the production of processed potatoes from lower solids content varieties produced in the East as well as the higher solids types from the West. Earlier processes, such as potato granules, only worked with western varieties.28

Instant potato flakes were introduced commercially in 1957 and became an "instant" success; by 1960 six processors turned more than four million bushels of potatoes into flakes. Production increased after that because producers learned how to use the trimmings from the initial peeling process and potatoes that could not be sold due to irregularities in size and shape. In the 1960s potato consumption had not only rebounded; consumption was now expanding due to the availability of new and high quality convenience foods. Instant mashed potatoes led the way, but potato flakes were soon being used industrially in coatings, ingredients, and fabricated foods.

Miles Willard, who had been instrumental in the research conducted at the ERRC in the 1950s, had gone into the private sector, where he developed a whole new class of potato chip-like snack foods using reconstituted potato flakes. Called "crisp," these products included Pringles® the market for these chips exceeded $1.4 billion in 2000. In 2003 more than 2.4 billion pounds of potatoes were turned into dehydrated potato flakes in the United States. The United States Potato Board estimates that 10% of the U.S. potato crop is used in dehydration processes, with half of that number turned into potato flakes (compared to 30% for granules and 20% for potato pieces).

Processed potato flakes have been used as rations by the U.S. military and they are a key component of international food aid programs because of their long shelf life. In 2004, the USDA obtained nearly five million pounds of potato flakes at a cost of nearly two million dollars for shipment to Moldava. Similarly, millions of pound of potato flakes are purchased by the USDA annually for use in the National School Lunch Program and other domestic child nutrition and food assistance projects.

Drying Fruits and Vegetables: The Explosion-Puffing Process

By the mid-1970s research on the potato flake process was over and the commercial applications of the process were assured. This enabled researchers at the Eastern Regional Research Center—Laboratory Chief Eskew and chemical engineers Cording, Nelson Eisenhardt, John Sullivan, Michael Kozempel, Gerald Sapers, Rich Konstance, Mary Jo Egoville, and others—to shift their attention to developing other methods for drying fruits and vegetables. Drying fruits and vegetables as a means of preserving them had been used in ancient times. But the two most commonly employed methods—hot-air drying and freeze drying—had limitations. Dehydrating pieces of fruit or vegetable by hot air is slow as is the re-hydration process. The flavor of the re-hydrated pieces often is not good because of the long exposure to high temperatures during drying. Freeze-dried products re-hydrate quickly and their quality is superior to the hot-air dried products, but the drying time is even slower and thus more expensive.29

A third process—developed at the ERRC—incorporates explosion puffing in the dehydration process. Cording had observed that air-dried pieces of fruits and vegetables collapsed on themselves, so he hypothesized that if the pieces were puffed up, this would open the inside in a honeycomb effect, making drying easier and quicker.30 The resulting product is similar in quality to the freeze-dried version, but the re-hydration times are even faster. This means that processing costs are much less expensive. In addition, the texture and flavor of the re-hydrated fruits and vegetables compares well with fresh cooked food. The explosion puffing process yields low-moisture—less than four percent—fruit and vegetable pieces. Many fruits and vegetables were processed using explosion puffing; for the most part, the re-hydrated pieces exhibited excellent texture, color, and flavor. In addition, the pieces stored well. The explosion puffing process produced a rapidly reconstituted, high quality, and inexpensive product that tasted fresh.31

Eisenhardt initially was in charge of working on fruits; Sullivan on vegetables.32 Research quickly established that raw fruits and vegetables would disintegrate when explosion puffed. The research also showed a relationship between moisture content of the product and the pressure used. This relationship differed depending on the food that was placed in the puffing gun. In any event, the process aimed at maintaining the porosity of the pieces (since the porosity actually increases in explosion puffing, large pieces could be dried) because porosity made the removal of water easy and rapid.

Initially the fruit or vegetable is hot-air dried to a moisture content between 15% and 35%, a level at which the piece attains a degree of rigidity. The partially-dried pieces are then fed into the "puffing gun." The initial experiments were carried out in a small gun that was heated by an external gas flame. The vegetable or fruit pieces were further heated in the gun while the gun rotated at a speed sufficient to tumble the pieces. Chamber pressure in the gun resulted from steam released from the heating of water in the pieces. In the small gun, the time required to obtain the requisite pressure varied from seven to fifteen minutes at which point the product exploded from the gun with a loud bang. The vegetable or fruit piece expanded—"puffed"—during the explosion.33

The small gun used in the early experiments allowed the researchers to test the feasibility of the explosion puffing process on many varieties of fruits and vegetables. As one of the researchers said "We certainly did not run out of products, we just ran out of time."34 Soon, the process was scaled up with the installation of a large commercial cereal-puffing gun to test commercial-type feed rates on large batches to get reasonable cost estimates. But both the small and large guns had drawbacks: the rough surfaces in the cast iron guns caused food pieces to stick and scorch instead of tumbling feely; they had to be opened and closed manually; and the sealing ring was made of lead.

A second large gun was constructed to eliminate some of these problems: the interior was sand-blasted and nickel-plated and a heat-tolerant rubber gasket was used for sealing instead of lead. This experimental puffing gun was designed specifically for use on large batches of fruits and vegetables and not for puffing cereals. It was constructed to be heated internally by superheated steam and externally by gas burners and the heating cycle was reduced to less than two minutes. The new gun produced vegetable and fruit pieces of superior color and flavor.

Batch-scale production was useful for research purposes, but it was too labor intensive for commercial use. To lower processing costs, a Continuous Explosion Puffing System (CEPS) was developed and built by Cording and Wolfgang Heiland and R.G. Mercado. This device—which reduced costs by running continuously—separated the two major functions: heating and explosion puffing. The heating is done in the main chamber by dispersing superheated steam. The explosion puffing takes place when the discharge piston is released. This reduces the pressure in the discharge chamber from that in the heating chamber to the atmospheric level. The resulting explosion produced a better product with reduced labor costs.35

CEPS was initially developed to produce dried potatoes and carrots, but was later applied to apples, blueberries, pears, celery, beets, sweet potatoes, turnips, rutabagas, onions, peppers, mushrooms, and other commodities.36 In addition to the engineering research, the ERRC conducted extensive quality control studies to test shelf life, flavor, and texture. John Sullivan, Gerald Sapers and others recognized early the need to control enzymatic browning and conducted numerous experiments and studies on flavor control, discovering for example the utility of injecting nitrogen gas with the steam during puffing to prevent deterioration of quality over time.37

The explosion puffing process has been used most successfully in the production of high-quality dehydrated carrot pieces and blueberries. Puffed carrots work well in quick-cooking dehydrated soup mixes where rapid re-hydration occurs, and they have been marketed by companies in the United States and in Europe, China, and India. Puffed potatoes are marketed as ingredients in meals for campers and for emergency rations. Explosion-puffed blueberries have been marketed over the years.

Research Notes and Further Reading

Research Notes

- There are many excellent works on the 1950s, but for a good overview, see David Halberstam, The Fifties (New York, Villard Books, 1993).

- Philip B. Dwoskin and Milton Jacobs, Potato Flakes — A New Form of Dehydrated Mashed Potatoes: Market Position and Consumer Acceptance in Binghamton, Endicott, and Johnson City, New York, U.S, Department of Agriculture, Agricultural Research Service, Marketing Division: Marketing Research Report No. 186 (1957): 2. The researchers were aware of the problems plaguing the potato crop. Interview with Michael Kozempel, conducted by Judah Ginsberg, January 30, 2007; interview with John Sullivan, conducted by Judah Ginsberg, January 31, 2007.

- On American agriculture in the 20th century, see Bruce Gardner, American Agriculture in the Twentieth Century: How It Flourished and What It Cost (Cambridge, Mass.: Harvard University Press, 2002).

- To avoid confusion, the facility will be referred to by its current name, the Eastern Regional Research Center.

- Roderick K. Eskew, Howard I. Sinnanmon, Joseph B. Claffey, Nicholas C. Aceto, and James Cording, Jr., Engineering Research at the Eastern Utilization Research and Development Division: A 25th Anniversary Review, U.S. Department of Agriculture, Agricultural Research Service (April 1966).

- Philip B. Dwoskin and Milton Jacobs, Potato Flakes — A New Form of Dehydrated Mashed Potatoes: Market Position and Consumer Acceptance in Binghamton, Endicott, and Johnson City, New York, U.S, Department of Agriculture, Agricultural Research Service, Marketing Division: Marketing Research Report No. 186 (1957): 2.

- Ibid. M.J. Willard, V.M. Hix, and G. Kluge, "Dehydrated Mashed Potatoes– Potato Flakes," Chapter 13 in Potato Processing, edited by William F. Talburt and Ora Smith, 4th edition, AVI Book (New York: Van Nostrand Reinhold Company, 1987), p. 558.

- J. Cording, Jr., M.J. Willard, R.K. Eskew. P.R. Ediwards, and J.F. Sullivan, Potato Flakes. A New Form of Dehydrated Mashed Potatoes. II. Some Factors Influencing Texture. U.S. Department of Agriculture, Agricultural Research Service, ARS 73-9.

- Miles Willard, "Potato Processing: Past, Present and Future," American Potato Journal 70 (1993). P. 406; W.F. Talburt, "History of Potato Processing," Chapter 1 in Potato Processing, p. 1.

- Talburt, "History of Potato Processing," p. 2; Willard, "Potato Processing," p. 406.

- On potato starch, see R.H. Treadway, "Potato Starch" Chapter 15 in Potato Processing

- On potato chips, see Talburt, "History of Potato Processing," p. 5; O. Smith, "Potato Chips," Chapter 10 in Potato Processing. For a good overview of the various potato processes, see R.H. Treadway, "Recent Developments in Processed Potato Products," American Potato Journal, 33 (1956).

- Interview with Michael Kozempel, conducted by Judah Ginsberg, January 30, 2007. On potato granules, see W.F. Talburt, F.P. Boyle, and C.E. Hendel, "Dehydrated Mashed Potatoes," Chapter 12 in Potato Processing.

- Willard, et al., "Dehydrated Mashed Potatoes," p. 557.

- Miles J. Willard, Jr., James Cording, Jr., R.K. Eskew, P.W. Edwards, and John F. Sullivan, "Potato Flakes. A New Form of Dehydrated Mashed Potatoes: Review of Pilot Plant Process," American Potato Journal 33 (1956): 28.

- Interview with John Sullivan, conducted by Judah Ginsberg, January 31, 2007.

- James Cording, Jr., Miles J. Willard, Jr., Roderick K. Eskew, and John F. Sullivan, "Advances in the Dehydration of Mashed Potatoes by the Flake Process," Food Technology, Vol. 11, No. 4 (1957): 236.

- The researchers at the ERRC turned out numerous reports on their progress, several of which discuss the cooking process. See, in particular, Cording, et al., "Advances in the Dehydration of Mashed Potatoes by the Flake Process,"; Willard, et al., "Potato Flakes. A New Form of Dehydrated Mashed Potatoes,"; Cording, et. al., Potato Flakes. A New Form of Dehydrated Mashed Potatoes. Much of the discussion that follows is based on these and other reports and interviews with researchers.

- Willard, et al., "Potato Flakes. A New Form of Dehydrated Mashed Potatoes," p. 29.

- Kozempel interview.

- Kozempel and Sullivan interviews.

- Kozempel interview.

- See J. Cording, Jr., J.F. Sullivan, and R.K. Eskew, A New Form of Dehydrated Mashed Potatoes. IV. Effects of Cooling After Precooking, U.S. Department of Agriculture, Agricultural Research Service. ARS 73-27.

- Kozempel and Sullivan interviews. A number of the reports and articles cited above discuss cell rupture. On cooking time, see Willard, et. al, "Dehydrated Mashed Potatoes - Potato Flakes," Chapter 13 in Potato Processing

- Ibid.

- Interview with Gerald Sapers, conducted by Judah Ginsberg, January 30. 2007. Also, interviews with Kozempel and Sullivan. See also, Willard, et. al, "Dehydrated Mashed Potatoes - Potato Flakes," Chapter 13 in Potato Processing

- See, Cording, et al., Potato Flakes. A New Form of Dehydrated Mashed Potatoes. II. Some Factors Influencing Texture

- The information cited on this page comes from a number of sources: Interviews conducted by Judah Ginsberg with Michael Kozempel, Gerald Sapers, and John Sullivan; documents supplied by the Eastern Regional Research Center in its application for Landmark status; and M.J. Willard, V.M. Hix, and G. Kluge, "Dehydrated Mashed Potatoes - Potato Flakes," Chapter 13 in Potato Processing, edited by William F. Talburt and Ora Smith, 4th edition, AVI Book (New York: Van Nostrand Reinhold Company, 1987).

- J.F. Sullivan and J.C. Craig, "The Development of Explosion Puffing," Food Technology 38(2) (1984): 52. This paper proved a very useful source for this section.

- Interview with Gerald Sapers, conducted by Judah Ginsberg, January 30, 2007.

- Sullivan and Craig, "The Development of Explosion Puffing," p. 52.

- Sullivan was given control of both fruits and vegetables when Eisenhardt died. See interview with John Sullivan, conducted by Judah Ginsberg, January 31, 2007.

- Sullivan and Craig, "The Development of Explosion Puffing." See also, N.H. Eisenhardt, J, Cording, Jr., R.K. Eskew, and J.F. Sullivan," Quick-Cooking Dehydrated Vegetable Pieces: 1. Properties of Potato and Carrot Products," Food Technology 16(5) (1962): 143-146.

- Interview with Rich Konstance, conducted by Judah Ginsberg, January 31, 2007.

- On CEPS, see W.K. Heiland, J.F. Sullivan, R.P. Konstance, J.C. Craig, Jr., J. Cording, Jr., and N.C. Aceto, "A Continuous Explosion Puffing System, Food Technology 31(11) (1977): 32-22 and J.F. Sullivan, R.P. Konstance, N.C. Aceto, W.K. Heiland, and J.C. Craig, Jr., "Continuous Explosion-Puffing of Potatoes," Journal of Food Science 42 (1977): 1462-1463, 1470.

- Sullivan and Craig, "The Development of Explosion Puffing," p. 55.

- J.F. Sullivan, "Control of Non-enzymatic Browning in the Dehydration of Fruits and Vegetables" Progress in Food and Nutritional Science 5 (1981): 377-393.

Further Reading

- History and Accomplishments (Eastern Regional Research Center)

Landmark Designation and Acknowledgments

Landmark Designation

The American Chemical Society designated the development of dehydration processes as a National Historic Chemical Landmark in a ceremony at the United States Department of Agriculture ARS Eastern Regional Research Center in Wyndmoor, Pennsylvania, on April 18, 2007. The plaque commemorating the event reads:

Chemists, chemical engineers, and food technologists at the Eastern Regional Research Center developed innovative dehydration technologies, most notably the potato flake process and explosion puffing. These technologies created opportunities for the development of novel, high-quality convenience foods and food ingredients for domestic and global markets. Instant mashed potatoes and formulated potato crisps, both made from potato flakes, are among the most popular and recognizable food products ever created. These food dehydration technologies increased U.S. potato production and utilization, provided key products for food aid programs, and made a lasting and significant impact on the ways in which foods are processed worldwide.

Acknowledgments

Adapted for the internet from “Development of Dehydration Processes,” produced by the National Historic Chemical Landmarks program of the American Chemical Society in 2007.

Back to National Historic Chemical Landmarks Main Page.

Learn more: About the Landmarks Program.

Take action: Nominate a Landmark and Contact the NHCL Coordinator.