Universal Oil Products (UOP) Riverside Laboratory

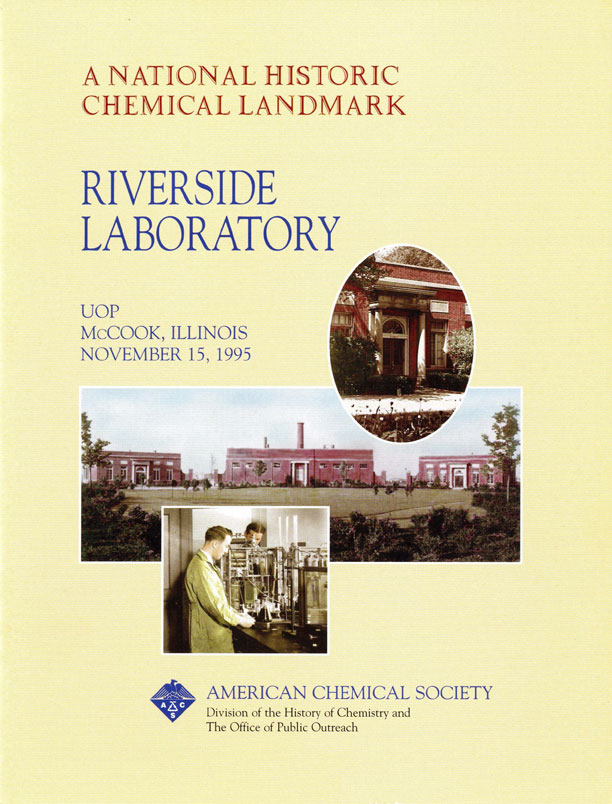

Dedicated November 15, 1995, at UOP Riverside Laboratory (now a Honeywell International, Inc., company) in McCook, Illinois.

The Universal Oil Products (UOP) Riverside research and development laboratory was conceived in 1921 by Hiram J. Halle, the chief executive officer of Universal Oil Products, as a focal point where the best and brightest scientists could create new products and provide scientific support for the oil refining industry. By 1921, that industry was growing rapidly as increasing numbers of automobiles led to greater demand for refined oil products. The establishment of Riverside gave independent oil refiners access to scientific research that allowed them to compete with the major oil companies. Halle also thought the laboratory would make a positive statement about the influence of his new organization.

Contents

Foundations of Universal Oil Products

Universal Oil Products was founded in 1914 to exploit the market potential of patents held by inventors Jesse A. Dubbs and his son, Carbon Petroleum (C. P.) Dubbs. Perhaps because he was born in Pennsylvania oil country, Jesse Dubbs was enamored with the oil business. He even named his son Carbon after one of the elemental constituents of oil. Later, Carbon added the P. to make his name "euphonious," he said. People started calling him "Petroleum" for fun, and the name stuck. C. P.'s son and grandson were also named Carbon, but each had a different middle initial.

Jesse was an inveterate tinkerer who developed, for example, a protective jelly for miners, a process for manufacturing harness oil, and a means of distilling the sulfur out of crude oil. He talked about harnessing the power of active volcanoes. Although a pharmacist by trade, he wandered the oil fields of the world from Russia to South America. Once he was kidnapped by Mexican bandits and held for $10,000 ransom. Dubbs was the first in town to purchase an automobile.

Dubbs moved to California, went bankrupt, then bounced back with new inventions, including one in 1909 for demulsifying oil to produce asphalt. His son, C. P., arranged a meeting with executives from a Midwest company called Standard Asphalt & Rubber Company. That company was one of many owned by J. Ogden Armour, a multimillionaire whose father had founded Armour & Company, the world's largest meat-packing organization.

Armour acquired new investments, especially those involving technology, like a collector acquiring antiques. Although Armour wanted to buy the Dubbs's patents because he thought they might be useful for his asphalt business, one of his lawyers, Frank Belknap, who avidly read everything written on the developing oil industry, realized that the process might prove even more valuable for cracking oil into gasoline. Belknap also had noted that the Dubbs patents predated those already in existence.

With the patents in hand, Armour formed Universal Oil Products and hired Hiram Halle, an astute businessman, to run the infant company. UOP established a plant in Independence, Kansas, to prove that the Dubbs process did indeed crack oil. Crude oil contains little material that can be used as gasoline. Cracking breaks up larger oil molecules and increases the yield of gasoline and other light distillates.

Along with the patents, Armour acquired the services of C. P. Dubbs to help prove that Jesse's patent could crack oil. C. P., who inherited his father's knack for tinkering, was a blunt man with a temper as volatile as the product he hoped to produce. Easily bored with routine tasks, C. P. began experimenting with new processes. Halle frequently had to order the inventor to get back to the original task of validating his father's patents. C. P.'s tinkering, however, led to the development of a new process, called clean circulation, which eventually would revolutionize petroleum refining. The recirculation that was at the heart of this new process enabled Dubbs to dilute the crude oil to prevent coke formation and the subsequent unit shutdown required for its removal.

Armour lost his fortune when the bottom dropped out of the meat-packing business at the end of World War I. Creditors picked apart his business empire but ignored UOP as little more than a handful of dubious patents. In its first decade, UOP had failed to earn any money. Armour died before profits materialized, but his widow became wealthy again in 1931 when UOP was sold for $25 million to a consortium of six major oil companies.

Riverside Laboratory: “Research Center of the World”

Before the infant company had earned any revenues from the Dubbs process, Halle decided that the company needed a more imposing presence if it were to become a major force in the refining industry. He wanted to build a facility that he hoped would become the "research center of the world." Halle commissioned Chicago's leading architectural engineers, Holabird and Roche (now Holabird & Root), to draw plans for a half-million dollar research and development laboratory that would serve as a showcase to the industry.

The chosen site, a 28-acre tract a dozen miles southwest of downtown Chicago, was near the Des Plaines River and on a spur of the Santa Fe Railroad's main line. A small independent refinery located on an adjacent plot would provide a convenient source of oil samples for experimental work. Within a reasonable radius were half a dozen large refineries that could become customers. As the nation's rail center, Chicago was a busy transfer point for oilmen traveling cross-country, and Halle reasoned that many could be persuaded to tour the laboratory and witness demonstrations of the Dubbs process during their layovers between trains.

The design for the front half of the property followed Halle's concept of "a quiet college campus." A tree-lined pebble drive would curve through the grounds past three low, colonnaded buildings of maroon brick. Here visitors could be greeted and led through facilities that included offices, laboratories, a drafting room, electrical and machine shops, first-aid facilities, and a library of polished white oak complete with easy chairs, parchment lamps, and a fireplace.

The back half of the property, beyond decorative wrought-iron gates, hedgerows, and a high fence, would house a Dubbs oil-cracking unit. The largest continuous cracking unit in the world at that time, it would be used for exhibition and as a pilot plant for process development and commercial runs.

Around the Dubbs unit would be tanks, process buildings, distillation columns, and other components of a working refinery. Halle calculated that the reaction of visitors would be that this combination of academic retreat and industrial plant "should certainly produce something."

The three original Riverside buildings still face the intersection of Joliet Road and Lawndale Avenue in McCook. These simple and functional brick buildings are embellished only with classic Doric columns. After their construction in 1921, they were called simply Building 1, Building 2, and Building 3.

Universal Oil Products Expands Hydrocarbon Science and Technology

In the spirit of Jesse and C. P. Dubbs, UOP scientists working in teams at Riverside have made key contributions to the science of hydrocarbon chemistry. Along with the research that led directly to commercial processes and products, UOP scientists enhanced the fundamental understanding of hydrocarbon rearrangement, isomerization, and polymerization. Rearrangement and isomerization are changes in the structure of carbon compounds that occur in the presence of strong mineral acids, such as sulfuric acid, or other catalysts. Polymerization is the formation of larger molecules by coupling smaller molecules to one another. These processes can be understood best by invoking carbocation theory, which was being formulated in the 1930s and 1940s. Work carried out at Riverside by Louis Schmerling, Herman Pines, Vladimir N. Ipatieff, Herman S. Bloch, Vladimir Haensel, and many other gifted scientists contributed greatly to the developing theory and helped to give it a firm and substantial experimental base. The many patents and scientific papers contributed by UOP scientists have gained an international reputation for the Riverside laboratory.

From the beginning, the scientists at Riverside were innovators in using pilot plants to commercialize scientific discoveries. Pilot plants are scaled-down units that simulate commercial processes for the purposes of evaluating process variables, estimating yields, and troubleshooting. Pilot plants remain an essential element today in the development of processes for the petroleum and petrochemical industries.

Although the development of modifications and improvements to the Dubbs clean circulation process dominated Riverside's early days, the expanding scientific staff soon began to explore new areas. During the period between World Wars I and II, when chemists were just beginning to learn how to use catalytic techniques to refine crude oil into petroleum and petrochemical products, many of the world's top scientists in that field were clustered in Riverside.

UOP's first professional chemist at Riverside was Gustav Egloff. He worked with Halle to recruit other research scientists to the Riverside staff. Among them was Clarence "Larry" Gerhold, who was hired in 1929, having just received his master's degree in chemical engineering from the University of Illinois. The need for smoother-running automobile engines led Gerhold to propose, soon after arriving at Riverside, a new process to increase the octane number of gasoline. Octane number refers to the anti-knock characteristics of the gasoline. The higher the octane number, the less knocking, and consequently, the engine performs more efficiently.

Gerhold developed the concept of recracking, or reforming, which took the products of cracking from a Dubbs unit or straight-run distillation and heated them to rearrange the oil molecules, thus increasing their octane number. Gerhold's process, called thermal reforming, consisted simply of a heating coil and a fractionation column, in which materials are separated based on boiling range. Thermal reforming almost doubled the octane of gasoline with only a 20% loss of volume.

In 1931, Vladimir N. Ipatieff, a pioneer in the field of catalysis, arrived at Riverside after defecting from his native Russia. Within a year, Ipatieff developed a polymerization process for the recovery of usable gasoline from the waste gases generated by thermal reforming. His team of scientists had learned that passing waste gas over diatomaceous earth impregnated with phosphoric acid converted the gas into a liquid petroleum product he called polymer gasoline. By 1935, the first UOP polymerization plant was processing 3 million cubic feet of gas and recovering 15,000 gallons of gasoline per day.

The principal mission of the researchers at Riverside was the development of processes and products for the oil refining industry. However, at times, with management's tacit approval, they side-stepped that mission to work on basic hydrocarbon research—sometimes with unanticipated results. For example, processes for catalytic alkylation and isomerization developed by Ipatieff's team and originally dismissed as having no commercial value ultimately led to the formulation of high-octane fuels.

The alkylation process originally involved the use of a catalyst of aluminum chloride (later hydrofluoric and sulfuric acids) to combine an olefin with a paraffin to produce a high-octane product that could be blended into gasoline. The announcement of this process transformed the existing rules of hydrocarbon chemistry by showing that supposedly inert paraffins could participate in chemical reactions under relatively mild conditions.

Isomerization was also catalyzed by aluminum chloride. Passing butane over the catalyst produced isobutane, which could be used as an alkylation feedstock.

Catalytic alkylation and isomerization contributed to the development of high-performance aircraft by providing blending components for the formulation of high-octane aviation fuel. During World War II, Allied aircraft burning 100-octane fuel had a significant speed advantage over German aircraft that used 87-octane fuel. This advantage was a critical factor in the 1940 Battle of Britain.

In 1949, a new, more-selective, and higher-yielding process for catalytic reforming, called Platforming®, was developed at Riverside by Vladimir Haensel. Its trade name originated from the fact that the active catalyst contained a small amount of platinum on alumina.

The Platforming® process dramatically changed petroleum refining by generating large volumes of high-octane, aromatics-rich gasoline at previously unattainable yields. The first Platforming® unit, located at Old Dutch Refinery in Muskegon, Michigan, came on-stream in 1949. The unit produced 93-octane leaded gasoline.

The availability of large quantities of hydrogen, generated as a by-product of the Platforming® process, spawned several additional processes for the hydrorefining and hydrotreating of petroleum feedstocks. As the use of heavier feedstocks became more common, refiners were forced to use hydrotreating processes to remove the sulfur and nitrogen that contaminated catalysts and shortened their useful lives.

The Platforming® process also advanced the petrochemical industry by making commercially viable quantities of aromatic hydrocarbons available to the synthetic rubber and fiber industries that blossomed after World War II. A single Platforming® unit coupled to a Udex extraction unit, which was the first major commercial process to extract aromatics from petroleum fractions, provided more high-purity aromatics than the entire coal tar industry produced during World War II.

The Universal Oil Products Legacy

The inventive minds of Riverside's scientists developed many other novel products and processes. During World War II, Riverside's chemists developed a process to make toluene, which was used in the manufacture of TNT. Petrochemical manufacturers use UOP processes to produce many of the raw materials for the clothing industry. Many of today's plastics would not be possible without technologies pioneered at Riverside. The manufacture of biodegradable linear alkylbenzene detergents is based on separations technology developed at Riverside. The basic patent for the food-grade antioxidant BHA (butylated hydroxy anisole) originated at Riverside in 1954. Riverside researchers also developed a series of phenylenediamine derivatives, which are used as antioxidants and antiozonants in the rubber, plastics, and fuel industries.

Between 1921 and 1955, Riverside research resulted in 8,790 U.S. and foreign patents and provided the foundation on which UOP built its success. When UOP opened a new research center in Des Plaines, Illinois, in 1955, Riverside's role changed. Riverside became UOP's pilot plant center and was charged with converting the results of basic research into commercially viable processes. For example, Riverside pilot plants were instrumental in the development of the UOP Sorbex process, a simulated countercurrent-flow separation technology that has applications in the petrochemical, food and beverage, and pharmaceutical industries. More than two-thirds of the world's para-xylene, which is ultimately used for the production of fibers and high-performance plastics, is obtained from the Sorbex process.

An important financial contribution linked to Riverside and UOP was the establishment of The Petroleum Research Fund in partnership with the American Chemical Society. In 1931, UOP was acquired by a consortium of major oil companies (Shell Oil Company, Standard Oil Company of California, Standard Oil Company of Indiana, Standard Oil Company of New Jersey, The Texas Company, and N. V. de Bataafsche Petroleum Maatschappij). Later, the Justice Department began an investigation of this arrangement as a possible violation of antitrust laws. The major oil companies decided to donate the assets of UOP to establish a trust, entitled The Petroleum Research Fund, to be used to support fundamental research. The American Chemical Society was named the income beneficiary of the trust.

In 1959, the trust sold its UOP holdings in a public offering. Today, the income from the trust provides more than $10 million a year, which ACS uses to administer grants to universities worldwide.

Early Universal Oil Products Researchers

Carbon Petroleum (C. P.) Dubbs. Using his father's patent as a starting point, C. P. developed a better method of cracking oil: the Dubbs clean circulation process. Soon, the Dubbs process was used worldwide for refining crude oil. During his career, C. P. Dubbs obtained 140 patents.

Hiram J. Halle. More businessman than scientist, Halle nevertheless nurtured an atmosphere of respect for research in which top scientists thrived. In 1914, J. Ogden Armour hired him to manage the newly created Universal Oil Products company, which had as its main asset the Dubbs patents for cracking oil. Halle was elected president of UOP in 1919, the year C. P. Dubbs perfected a continuous-circulation process that proved superior to the original patent and to any other method of refining oil. Halle chose to license the Dubbs process to all refiners rather than enter the refining business in competition with them. This decision became the business formula under which UOP still operates. Halle remained in charge of UOP until his death in 1944 at age 76.

Gustav Egloff. UOP's first professional chemist, Egloff was hired in 1915 to assist C. P. Dubbs. People in the oil industry knew him as "Gasoline Gus" because of his ability to explain complicated processes to reporters. He served as president of the American Institute of Chemists from 1942 to 1946. Egloff died in 1955. Although he was granted 280 patents, his most important role at UOP may well have been his recruitment of the outstanding scientists who followed him.

Clarence G. "Larry" Gerhold. Within three months of his arrival at Riverside in 1929, Gerhold developed a new cracking process, called thermal reforming, that used gasoline, rather than crude oil, as a feedstock. He was also the prime inventor of UOP processes that separate aromatics from other hydrocarbons. These processes contributed to the explosive growth in the aromatic derivatives branch of the petrochemical industry. His work at Riverside was the basis for the ultimate development of the UOP Sorbex® processes, which provide continuous adsorption separations. Gerhold was appointed manager of the Riverside laboratory in 1945. He was the recipient of 78 patents.

Vladimir N. Ipatieff. Chairman of the Czar's Commission for the Preparation of Explosives during World War I, Ipatieff survived the purges following the Russian Revolution and remained a leading chemist in Russia. In 1930, at age 62, Ipatieff defected while attending a conference in Berlin. He came to work for UOP at Riverside the following year and remained for more than 20 years. Ipatieff's specialty was catalysis. He had dual appointments as research director of UOP and professor of chemistry at Northwestern University in Evanston, Illinois. At Riverside, he focused more on basic hydrocarbon and catalytic research than on commercial products.

Nevertheless, he developed many important refining processes. He was one of only three industrial chemists to receive the prestigious Willard Gibbs Medal of the Chicago Section of the ACS since the award's inception in 1911. Because he played a leading role in the development of UOP's polymerization, alkylation, and isomerization processes, Ipatieff made a major contribution to the development of the high-octane aviation fuel that helped the Allies win World War II. He earned 174 patents while working for UOP.

Herman Pines. A polish immigrant, Pines came to Riverside in 1930, directly after obtaining his degree from the University of Chicago. During the 1930 he worked with Ipatieff on a new process called catalytic alkylation. He also collaborated with Ipatieff on the development of UOP's isomerization and polymerization processes. Pines earned 145 patents and was the recipient of the American Chemical Society Award in Petroleum Chemistry in 1981.

Louis Schmerling. Schmerling joined UOP in 1935 and began the pioneering research that led to a more fundamental understanding of hydrocarbon chemistry. He obtained 298 patents and published more than100 papers. He received the American Chemical Society Ipatieff Prize in Catalytic Chemistry in 1947 and the American Chemical Society Award in Petroleum Chemistry in 1951.

Herman S. Bloch. Bloch began working at UOP in 1936 after receiving his doctorate at the University of Chicago. Among his many honors are the 1974 E. V. Murphree Award in Industrial and Engineering Chemistry from the American Chemical Society and his election to the National Academy of Sciences in 1975. He served as chairman of the American Chemical Society Board of Directors from 1974 to 1976. Much of his fundamental research, which was carried out at Riverside, led directly to technology used to protect the environment, specifically the synthesis of biodegradable detergents and the development of catalytic exhaust mufflers. He also developed catalytic processes for the isomerization of light paraffins that permitted the elimination of tetraethyl lead from gasoline. He was granted 268 patents.

Vladimir Haensel. When Haensel arrived at UOP in 1937, he became Ipatieff's protégé. During his years at Riverside, he developed the Platforming® process, which was unique because it used rare platinum as a catalyst for reforming petroleum distillate fractions. The Platforming® process increased both the yield of gasoline and its octane level. Among his numerous awards and honors are the American Chemical Society Award in Petroleum Chemistry in 1952, the Perkin Medal for outstanding work in applied chemistry in 1967, the National Medal of Science in 1973 for "his outstanding research in the catalytic reforming of hydrocarbons, which has greatly enhanced the economic value of our petroleum resources," and the National Academy of Sciences Award for Chemistry in Service to Society. Haensel was granted 139 patents.

Landmark Designation and Acknowledgments

Landmark Designation

The American Chemical Society designated the UOP Riverside Laboratory (now a Honeywell International, Inc. company) as a National Historic Chemical Landmark in a ceremony in McCook, Illinois, on November 15, 1995. The plaque commemorating the event reads:

This research and development complex was established by the founders of Universal Oil Products (later named UOP) to develop key products for the oil-refining industry. The processes created here profoundly affected the refining, treatment and conversion of crude oil and the development of the petroleum and petrochemical industries. Conceived as a combination of quiet academic retreat and industrial plant, Riverside attracted many of the world's leading petroleum scientists and a dedicated support team. Between 1921 and 1955, Riverside research resulted in 8,790 U.S. and foreign patents. Today, Riverside research focuses on catalyst development and pilot-plant operations that test catalyst performance and optimize processing conditions.

Acknowledgments

Adapted for the internet from “Riverside Laboratory,” produced by UOP for the National Historic Chemical Landmarks program of the American Chemical Society in 1995.

Learn more: About the Landmarks Program

Take action: Nominate a Landmark and Contact the NHCL Coordinator