The materials industry brings new and innovative materials to market, providing improved alternatives for current applications and new solutions to global challenges. The broad space of materials includes new innovations, renewables, packaging, and electronics, as well as materials for building, protection, and transportation. Safe and sustainable development requirements are critical to the success of materials and their ability to meet evolving needs. Materials often take a quieter approach to entry than, for example, pharmaceutical drugs. But by no means is the entry any less complex or safe: A chemical ingredient must be managed throughout its life, including disposal, and additional considerations must be taken about its end of life.

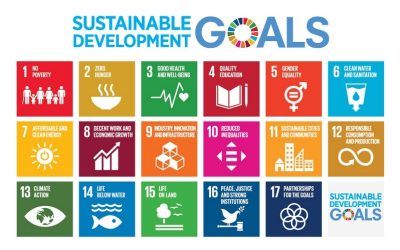

The United Nations has created 17 Sustainable Development Goals (SDGs) to help drive peace and prosperity for the planet are a part of the UN’s 2030 agenda for sustainable development. Several of the goals serve as a blueprint and overlay directly with the materials industry to safely, and more eco-considerately, produce new materials. For example, how a material is produced is guided by goals #12 Responsible Consumption and Production, #14 Life below Water, and #15 Life on Land.

International laws have already been formed and will continue to evolve to support these goals. The EU’s registration, evaluation, authorization, and restriction of chemicals (REACH) regulation is a great example. REACH was put into force in 2007 to help address production and use of chemicals. Any chemical substance manufactured or imported into the EU in quantities of one ton or more needs to be registered, yet an exemption includes polymers, with specific guidance around polymer types, blends, and additives, which affects the materials industry.

REACH regulation also established the European Chemicals Agency (ECHA) as a managing agency. ECHA then established the Chemical Agents Directive as well as the Carcinogens and Mutagens Directive. The EU also has an OHSA (EU-OSHA) agency to manage information on occupational health and safety. An example of how REACH, ECHA, and EU-OSHA work together for the benefit of the materials industry includes supporting a key initiative for safer material production—substitution of hazardous chemicals.

In 1976, the US EPA established the Toxic Substance Control Act (TSCA) to regulate and screen chemicals that are produced or imported into the US. TSCA looks at the lifetime of a chemical and takes into account numerous safety considerations. The Resource Conservation and Recovery Act (RCRA) covers generating, transporting, treating, storing, and disposing waste (cradle to grave).

While the materials industry does not necessarily make a large splash in the news when a new material is brought to market, the implications of an unsafe material frequently have made headlines. For example, endocrine disruptors, chemicals that mimic and interfere with natural hormones, were unknown at one point. Through ever-progressing research and co-operation of supporting institutes, products containing these chemicals that are used in daily life become safer by substituting a material for an unsafe ingredient.

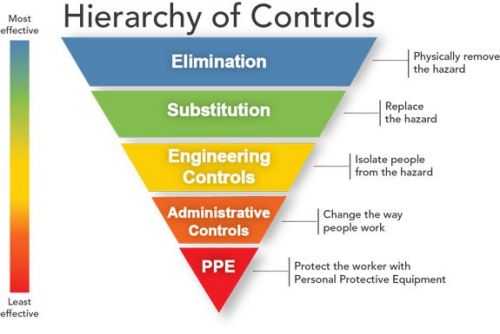

A common principle of safety from OSHA, similar to EU-OSHA, that applies in the development timescale in new material development is the hierarchy of controls. Elimination is a key principle in chemical risk management, with personal protective equipment being the last line of defense. This is true in the development of the materials and choosing materials to perform a certain function.

There has been steady movement in applying all of these goals and principles to new material development in industry. Safety and sustainability are no longer distinct attributes, as company strategies are required to meet minimum legislative requirements. And beyond that, companies are increasingly tasked with solving problems with more ethical consideration and in collaboration with customers.

This article has been edited for length and clarity. The opinions expressed in this article are the author's own and do not necessarily reflect the view of their employer or the American Chemical Society.

Kathleen is a new materials development leader at DuPont. She joined the company in 2010 after receiving a BS in chemistry from Rensselaer Polytechnic Institute and a Ph.D. in chemistry from the University of Florida. She was also a visiting polymer research scientist at the Max Plank Institute for Polymer Research, and it was this experience in Mainz, Germany, sparked her interest in sustainability after observing policy and culture differences where materials science could help. She has a fundamental structure-property background and has previously held roles in renewable materials research in films, coatings, foams, and fibers to enhance environmental benefits and new process research to reduce chemical usage. She is currently a materials development lead scientist in the safety business unit within Water and Protection, where she works on process and product development and helps commercialize new performance materials with a problem-solving and sustainability drive.