Green chemistry, sustainability and the circular economy are gaining in popularity with consumers and the global market. What do you think is driving this shift?

It may be useful first to define sustainability and green chemistry. Sustainable development refers to meeting present needs without compromising the ability of future generations to meet their own needs. It has gained a lot of publicity because the United Nations in 2015 adopted 17 Sustainable Development Goals (SDGs), trying to end poverty, protect the planet, and ensure that by 2030 people can enjoy peace and prosperity. Green chemistry is the design of chemical products and processes that reduce or eliminate the use and generation of hazardous substances. In fact, the goals of green chemistry are aligned with sustainability, and we can think of green chemistry as part of sustainability.

Indeed, green chemistry and sustainability are catching on. Consumers around the world are becoming more aware of the need to protect the environment, reduce energy and material usage, slow down the depletion of natural resources, and minimize waste, hazards, and risks. Sustainability is important to industry as well, and many businesses have embraced sustainability. In suitable cases, green chemistry can increase process efficiency, reduce waste, enhance safety, attract talent, and create new business opportunities and even greater sales for some applications. Thus, sustainability can be a competitive strategy for business.

In your 2020 comment in C&EN, you shared the critical role chemists and chemical engineers play in addressing the UN Sustainable Development Goals (SDGs). After spending part of your presidential year connecting with the diverse members of the chemistry enterprise working to solve many SDG-related challenges, can you cite some areas where you see reasons for optimism? And what are some of the most significant challenges in the near future?

The UN Sustainable Development Goals cover a broad range of topics. From ACS’s perspective, chemistry and chemistry-related activities can help in at least seven of them: 1) Zero hunger, 2) Good health and well-being, 3) Clean water and sanitation, 4) Affordable and clean energy, 5) Industry, innovation, and infrastructure, 6) Responsible consumption and production, 7) Climate action. Furthermore, five additional goals are considered foundational as the chemistry community strives for the seven SDGs: 1) Quality education, 2) Reduced inequalities, 3) Gender equality, 4) Decent work and economic growth, 5) Partnerships for the goals.

As we can see, these goals are noble and highly desirable but need a lot of concentrated efforts by major countries of the world, and the people involved. They require the attention and collaboration among leaders in government, business, and academia, and certainly among scientists and engineers. The active participation (and investments) of these stakeholders is probably the most significant future challenge.

As for progress, we can certainly see some bright spots in R&D. For example, the rapid developments of therapeutics, vaccines, and diagnostic tools in response to the pandemic are good examples of the collective efforts towards health. Continued R&D in agriculture and food packaging will ensure safe consumption and handling of food. In the area of clean water, polymeric membrane technologies and various absorbent materials have been employed to remove toxic substances from water. Progress is being made for supplying clean and sustainable energy to replace fossil fuels. Moreover, the number of publications in sustainability and green chemistry has drastically increased in the past few years, and active R&D is on-going in academia, industry, and government labs.

In the political arena, the U.S. House of Representatives (2019) and Senate (2020) passed a bill to direct the White House Office of Science and Technology Policy to support sustainable chemistry and develop a road map. The chemical industry is increasingly supportive of sustainability. For example, three major international companies, Procter & Gamble, DuPont, and Unilever, have all announced plans to implement substantial sustainability programs for their businesses. Several other companies have also announced plans for sustainable products or processes.

As for the foundational goals, certainly ACS has made a lot of efforts to support STEM education, foster partnerships, and reduce inequities. In fact, Diversity, Equity, Inclusion, and Respect (DEIR) is among the core values of ACS. Embracing and advancing inclusion in chemistry is one of the major goals in the ACS Strategic Plan.

Is there a way to simplify the plastics sustainability challenge so that it is more easily understood by the general public? There is a focus on single-use materials, yet large fractions of environmental plastics come from clothing, tires and non-packaging polymers. What solutions are needed to address the totality of the issue?

Because plastics are inexpensive, lightweight, and versatile, world production has substantially increased in the past 60 years. In 2018, over 359 million metric tons of plastics were manufactured across the globe. As most plastics do not break down naturally, they accumulate. Some data suggest that global plastic waste was 275 million metric tons in 2010, a large amount due to the prior years of waste. The largest contributors of waste are packaging, textiles, consumer and institutional products. In the U.S. in 2017, plastic products generation was 35.4 million tons, or 13.2 percent of municipal solid waste.

The problem is immense, and many people feel that we should consider the totality of the issue in the context of the plastic value chain, including design, reuse, repair, and recycling. An active area of research is the design of new or improved polymers that are more readily degradable, reusable, or recyclable. Also to be considered is the reduction of materials, energy, and waste in the production processes. The reuse option refers to using an object again for a similar application; an example is to re-extrude a used polymer (perhaps together with some new polymer) to produce a product. After use, some polymers may suffer loss of properties (e.g., due to hydrolysis or degradation). In such cases, a repair process may permit the polymer to be reused or repurposed. Recycling means converting an item into raw materials to be used again, usually for a completely new product. Although this can be energy intensive, perhaps with suitable polymer design, the conversion process may be more manageable and economical.

Although this is a difficult area, there are many opportunities for future developments. For example, approaches that can minimize polymer waste, such as use of agro-based materials, recycling of polymer waste, synthesis of more easily degradable or recyclable polymers, and minimization of polymer use should be helpful. New or improved polymer processes that entail reduced cost and energy, atom economy, reaction efficiency, and toxicity reduction should also be considered.

There is considerable confusion in society over the potential for biological solutions to our plastics issues. Biosourced, biodegradable, bioprocessed, and other terms seem to be confusing consumers. What role should bio play in plastics sustainability?

The current interest in bioplastics is driven by a number of economic, social, and political factors. Among them are decreased dependency on petroleum feedstock and relative price stability of agro-based products. Besides sustainability, biodegradability and environmental benefits, there are also increased economic opportunities for farmers and rural communities through value-added products from agricultural commodities. Many biobased polymers are also biodegradable, a desirable feature for environment disposal, with the added benefit of reducing microplastics. The question before us is how extensive a role can biobased materials play in replacing and/or supplementing petroleum-based plastics?

Perhaps it is useful to look at this issue from the historical perspective. Prior to the 1930s, natural raw materials were often used as polymeric products. It was only after WW2 that the low-cost of petroleum stimulated replacements of the natural materials, but replacements have been partial in many areas. e.g., wood versus plastic for furniture, cotton versus polyester for textiles, triglyceride oils versus acrylics in paints, cellophane versus polymers for packaging, protein and starch versus polymer in adhesives, and natural versus synthetic thickeners for aqueous formulations. Thus, natural raw materials can indeed contribute substantially to sustainability.

Of course, plastics are now ubiquitous. Applications seem almost unlimited, but a major concern is their enormous production output. Over the years, we have also learned to modify, fabricate, or formulate polymer products with outstanding end-use properties. In industrial applications, we know that cost/performance is the key to the success of the products. Thus, for biobased materials to play a major role in sustainability, we need to lower their cost and enhance their properties. These requirements are non-trivial, and often need a lot of scientific, engineering, marketing, and commercialization efforts. It is fair to say that “bio” can definitely play a role in sustainability, but we must keep in mind that this approach is not the only solution to the plastics issue.

Indeed, the terminologies involving “bio” can be confusing. Two key features of these materials are degradability and renewability. For example, natural raw materials, such as polysaccharides, proteins, and triglycerides, are certainly renewable and sustainable. Although most biopolymers are biodegradable, some are not. For example, ethanol can be polymerized into polyethylene; although biobased, it is not biodegradable.

Your work on biopolymer blends and bio-based packaging materials has high value, practical impact. Can you share some of the challenges and opportunities in this space?

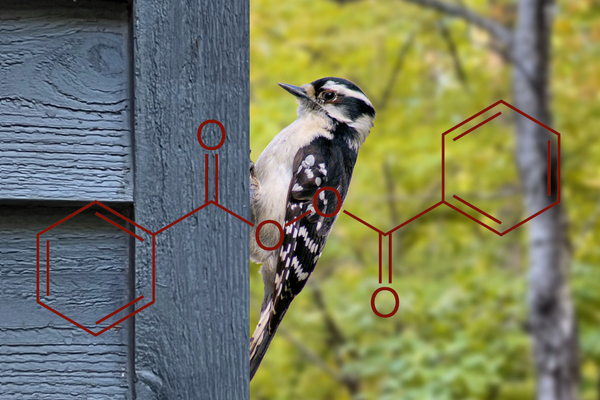

As discussed above, agro-based materials can be made from widely available raw materials, which are sustainable and biodegradable. Unfortunately, most of these materials (e.g., polysaccharides, proteins, triglycerides, and lignin) may not have the end-use properties needed for specific applications. Thus, for industrial product development, a major challenge is to improve the properties.

For example, polymer blending is one approach whereby we can quickly enhance the properties of a packaging film without chemical modification (e.g., the formation of a covalent bond). In this way, regulatory barriers and R&D expenditure can be reduced. Other approaches involve modifying film surfaces to render them less hydrophilic, designing biobased composites containing synthetic polymers to form semi-synthetic films, and incorporating of nanomaterials to strengthen film. Lastly, additives, such as essential oils and antioxidants, can be used for specific types of packaging. Because agro-based materials are structurally diverse, combinations and variations are possible, offering many opportunities for customization and optimization. Thus, this area of development has a lot of future possibilities.

H.N. Cheng obtained his B.S. from UCLA and his Ph.D. from the University of Illinois at Urbana-Champaign. In his R&D work, he has been active in developing and promoting green polymer chemistry as a platform to produce eco-friendly and sustainable products. As part of this work, he has been involved with the use of biobased materials, biocatalysis, green processing, and green methodology. He has also done a lot of work on polymerization theory and polymer NMR. He is currently a Research Chemist at USDA Southern Regional Research Center in New Orleans. Prior to 2009, he was Senior Research Fellow at Hercules Incorporated (now Ashland, Inc.) in Wilmington, Delaware, where he held various R&D and managerial positions.

He has authored or co-authored over 270 papers and 26 patent publications. He has organized 37 symposia at national meetings since 2000 and edited 21 books.

He was selected as a Fellow of the American Chemical Society (ACS) (2009), a Fellow of the ACS Polymer Chemistry Division (2010), and a Fellow of the ACS Agricultural and Food Chemistry Division (2018). He was the recipient of ACS Volunteer Service Award (2016), Tillmanns-Skolnick Award for Outstanding Service from the ACS Delaware Section (2006), Distinguished Service (2005) and Special Service (2015) Awards from ACS Polymer Chemistry Division, and ACS Delaware Section Award for research excellence (1994).

This article has been edited for length and clarity. The opinions expressed in this article are the author's own and do not necessarily reflect the view of their employer or the American Chemical Society.

Copyright 2022 American Chemical Society (All Rights Reserved)