FOR IMMEDIATE RELEASE

ACS News Service Weekly PressPac: December 09, 2015

‘Al dente’ fibers could make bulletproof vests stronger and ‘greener’

“High-Performance Polyethylene Fibers “Al Dente”: Improved Gel-Spinning of Ultra-High Molecular Weight Polyethylene Using Vegetable Oils”

Macromolecules

Bulletproof vests and other super-strong materials could soon become even tougher and more environmentally friendly at the same time with the help of extra firm, or “al dente,” fibers. Researchers report in ACS’ journal Macromolecules an innovative way to spin high-performance polyethylene fibers from natural fats, such as oils from olives and peanuts.

These materials, which are powerful enough to stop speeding bullets, can also be used for many other tasks that require strength. They recently played a key role in lifting a sunken ferry from a delicate ecosystem off the coast of Italy. The fibers also can serve as sails to catch wind, ropes for climbing and tying, and thin, sturdy surgical sutures that ensure wound healing. But making fibers for these applications with today’s commercial processes has drawbacks. For example, one of the methods requires large amounts of solvents that are flammable and toxic. The research group led by Theo Tervoort and Paul Smith from ETH Zurich wanted to find a more environmentally friendly route to produce these ultra-strong fibers.

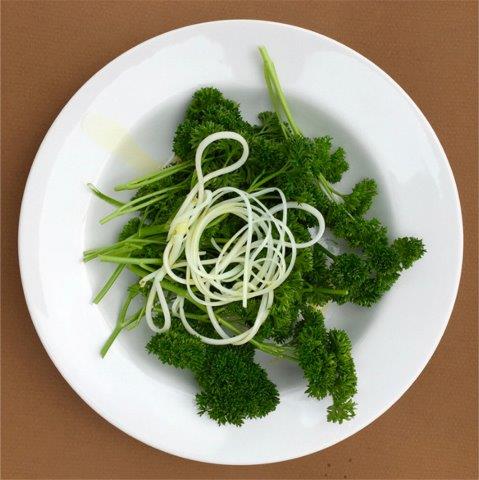

The researchers replaced the hazardous solvents with natural, safer alternatives, including extra virgin olive oil, peanut oil and stearic acid, which is a substance found in animal and vegetable fats. Their new approach was up to 250 percent more efficient than current methods. And resulting fibers were up to 2 times stronger than a current commercial version. With a nod to the culinary connection, the researchers dubbed their novel product al dente fibers.

High-resolution image