FOR IMMEDIATE RELEASE

ACS News Service Weekly PressPac: October 20, 2021

Lightweight electric wristband heaters for constant, portable warmth

“Wash-Durable Conductive Yarn with Ethylene Glycol-Treated PEDOT:PSS for Wearable Electric Heaters”

ACS Applied Materials & Interfaces

As the fall chill settles in across the U.S., people are getting out their cozy sweaters and electric blankets, or stocking up on handheld heat packets for extra warmth. But sweaters and blankets are bulky, and heat packs only work for a little while. Now, researchers reporting in ACS Applied Materials & Interfaces demonstrate a conductive, durable yarn for lightweight wearable heaters that are re-usable and provide constant, portable warmth.

Lightweight wearable heaters with heating elements embedded within the fabric could help keep people warm, but previous attempts have resulted in hot stiff wires or threads that cannot be safely washed. Recently, researchers have treated fabric and yarn with poly(3,4-ethylenedioxythiophene) and poly(4-styrenesulfonate). This flexible coating warmed up the materials and stayed in place after washing. However, the polymers were not conductive enough for personal heating, and some compounds added to make them more conductive could irritate the skin. So, Rawat Jaisutti and colleagues wanted to improve upon the two-polymer coating applied to yarn so that it could distribute heat at a safe operating voltage when sewn into fabric.

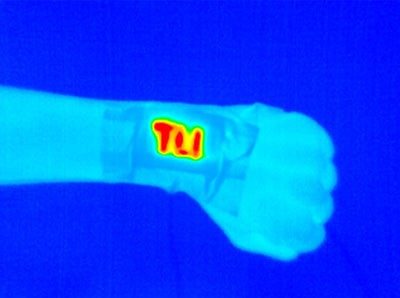

As a first step, the researchers dipped the polymer-coated cotton yarn into ethylene glycol, which is not irritating to human skin. When they applied voltage to the material, it warmed up, requiring lower voltages to reach high temperatures than some previously reported flexible heaters. Then the team washed treated yarn either repeatedly with water or once with detergent. They found that although in both instances there was a slight loss of conductivity, this loss was significantly less than a version without the ethylene glycol. Finally, the researchers sewed multiple pieces of the yarn into a “TU” pattern on a bit of fabric with an additional fabric backing. When the heater was connected to a three-volt power supply and attached to a person’s wrist, the heat distribution in the thermal wristband was steady as it was bent back and forth. The researchers say the wristband can also be powered by a battery via an external circuit for more portability.

The authors acknowledge funding from the Thammasat University Research Unit in Innovative Sensors and Nanoelectronic Devices, the Thailand Research Fund, the Thailand Office of Higher Education Commission and the National Research Council of Thailand.

###

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and all its people. The Society is a global leader in promoting excellence in science education and providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a leader in scientific information solutions, its CAS division partners with global innovators to accelerate breakthroughs by curating, connecting and analyzing the world’s scientific knowledge. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive press releases from the American Chemical Society, contact newsroom@acs.org.

Note: ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies.

Media Contact

ACS Newsroom

newsroom@acs.org

View larger image