FOR IMMEDIATE RELEASE

“Mechanochemical Activation of Silicone for Large-Scale Fabrication of Anti-Biofouling Liquid-like Surfaces”

ACS Applied Materials & Interfaces

When entering public restrooms, it’s hard not to dwell on what germs previous users have left behind in the toilet bowl. Imagine, instead, a self-cleaning system that doesn’t require a brightly colored gel. Researchers reporting in ACS Applied Materials & Interfaces have developed a simple, transparent coating that makes surfaces, like porcelain, more water-repellent. They show how this surface treatment effectively prevents bacteria from sticking to the inside of a toilet bowl.

Coatings can be applied to glass and porcelain to ensure water droplets easily slide off, preventing fog or bacterial films from developing, for example. To add this water-repellant property to surfaces, scientists typically engineer microscopic structures, like the tiny barbs and hooks on bird feathers, to trap air or oils between the surface and water droplets. But this approach is typically labor intensive and can change the appearance of the surface. Another approach is to graft slippery polymer chains onto a surface, and those polymers act like a permanent oil slick. However, this technique can involve harsh chemicals and isn’t feasible for use on everyday items. So, Mustafa Serdar Onses and coworkers wanted to find a more practical way to make polymer-grafted surfaces repel water and impede growth of bacterial films.

Their selected approach involved grinding poly(dimethylsiloxane) (PDMS), a silicone oil, in a ball mill for an hour. In the mill, small tungsten carbide balls bombarded the oil at high speeds, breaking apart some of the polymer’s chemical bonds and forming new molecules. The team hypothesized that the milled PDMS would graft quickly onto surfaces, such as glass or porcelain, forming a durable, oily layer.

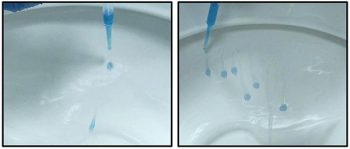

The researchers brushed the milled oil onto one side of a sterilized toilet’s bowl interior, leaving the other half untreated. Then they poured sterile human urine combined with E. coli and S. aureus bacteria into the toilet and subsequently swabbed what was left behind on both halves of the bowl. Bacteria culture tests showed that the PDMS-treated area inhibited 99.99% of the bacterial growth as compared to the untreated area. Additional experiments showed that both porcelain and glass surfaces coated with the milled PDMS strongly repelled water, suggesting that, in the first test, urine and bacteria slipped right down the treated toilet bowl’s wall. The researchers say that their transparent and colorless toilet bowl treatment method could be a practical way to self-sanitize shared surfaces for public health applications.

The authors acknowledge funding from the Erciyes University and the Scientific and Technological Research Council of Turkey.

###

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and all its people. The Society is a global leader in promoting excellence in science education and providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a leader in scientific information solutions, its CAS division partners with global innovators to accelerate breakthroughs by curating, connecting and analyzing the world’s scientific knowledge. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive press releases from the American Chemical Society, contact newsroom@acs.org.

Note: ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies.