FOR IMMEDIATE RELEASE

“A Layered Organic Cathode for High-Energy, Fast-Charging, and Long-Lasting Li-Ion Batteries”

ACS Central Science

In the switch to “greener” energy sources, the demand for rechargeable lithium-ion batteries is surging. However, their cathodes typically contain cobalt — a metal whose extraction has high environmental and societal costs. Now, researchers in ACS Central Science report evaluating an earth-abundant, carbon-based cathode material that could replace cobalt and other scarce and toxic metals without sacrificing lithium-ion battery performance.

Today, lithium-ion batteries power everything from cell phones to laptops to electric vehicles. One of the limiting factors for realizing a global shift to energy produced by renewable sources — particularly for the transition from gasoline-powered cars to electric vehicles — is the scarcity and mining difficulty of the metals, such as cobalt, nickel and magnesium, used in rechargeable battery cathode manufacturing. Previous researchers have developed cathodes from more abundant and lower cost carbon-containing materials, including organosulfur and carbonyl compounds, but those prototypes couldn’t match the energy output and stability of traditional lithium-ion batteries.

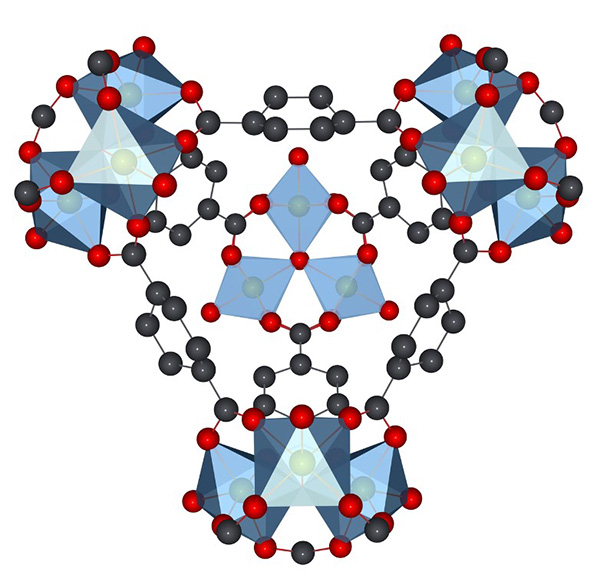

So, Mircea Dincă and his colleagues wanted to see if other carbon-based cathode materials could be more successful. They may have found a worthy candidate in bis-tetraaminobenzoquinone (TAQ). TAQ molecules form layered solid-state structures than can potentially compete with traditional cobalt-based cathode performance.

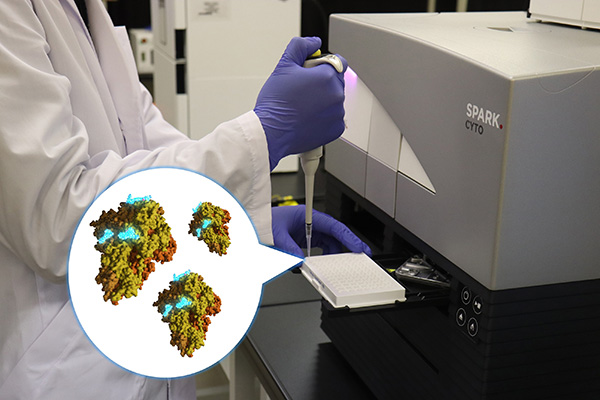

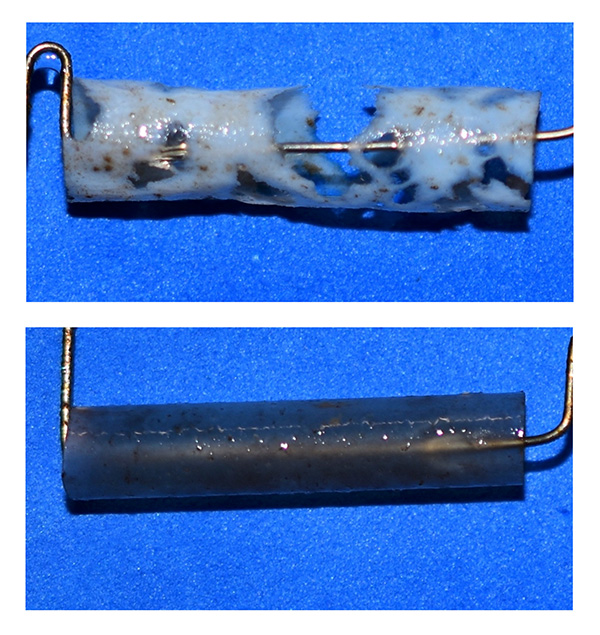

Building on their prior work that showed TAQ’s effectiveness as a supercapacitor material, Dincă’s team tested the compound in a cathode for lithium-ion batteries. To improve cycling stability and to increase TAQ adhesion to the cathode’s stainless-steel current collector, they added cellulose- and rubber-containing materials to the TAQ cathode. In the researchers’ proof-of-concept demonstration, the new composite cathode cycled safely more than 2,000 times, delivered an energy density higher than most cobalt-based cathodes and charged-discharged in as little as six minutes. The TAQ-based cathodes need additional testing before they appear on the market, but the researchers are optimistic that they could enable the high-energy, long-lasting and fast-charging batteries needed to help speed a global transition to a renewable energy future that’s cobalt- and nickel-free.

The authors acknowledge funding from Automobili Lamborghini S.p.A.

The authors have filed patent applications on this technology.

###

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and all its people. The Society is a global leader in promoting excellence in science education and providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a leader in scientific information solutions, its CAS division partners with global innovators to accelerate breakthroughs by curating, connecting and analyzing the world’s scientific knowledge. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive press releases from the American Chemical Society, contact newsroom@acs.org.

Note: ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies.