Key Takeaways:

- Corning shares how recent challenges in Wuhan, China has affected other company facilities

- Find out what applications Corning has in store for the automotive market

- Corning shares her view regarding material research vs. process research

In 2020, Corning announced that it will be providing Apple with a new material, Ceramic Shield, for its iPhone 12 line. What advantages does this hybrid of ceramic and glass have vs. your Gorilla Glass?

We have worked extensively with Apple over the years to solve tough problems and strategically invest in new products and technologies. Together with Apple’s team, we combined our deep expertise in materials science to develop a new-to-the world material, Ceramic Shield. And with Apple’s support, we scaled up several next-gen manufacturing processes to make the front cover of the latest iPhone lineup.

Gorilla Glass is a strengthened alumino-silicate glass while Ceramic Shield is a glass-ceramic. Glass-ceramics are materials that start with a specially formulated glass, which is then heat treated to develop crystals which are embedded in the glass matrix. Glasses do not exhibit this crystalline structure. In a glass-ceramic, the crystal structure within the glass matrix can impart differences to the optical, mechanical and thermal properties of the material.

Corning produces giant glass sheets for large screen TVs in its Wuhan, China factory. Did the challenges you confronted there give Corning a ‘head start’ on how to manage other company facilities as the pandemic progressed?

Our employees in Wuhan acted quickly and did an extraordinary job protecting the health and safety of our staff. They developed strict safety protocols, including assigning small working groups with designated plant entrances and lunch times to maintain social distancing.

These types of safety regulations enabled the plant to maintain continuous operation throughout 2020. There is no doubt that their proactive response, to what was a growing pandemic at the time, gave our security, health, IT, and transportation experts around the globe a head start, as the virus spread.

Our local leaders in China developed a playbook that was leveraged and customized for the specific needs in Europe, North America, and our many other global locations. From this playbook, our Corporate Medical team developed a set of health and safety guidelines that became an internal mantra for all employees.

What's the biggest question confronting your Inorganic Materials Research Group, as the pandemic winds down? Is it the same question confronting your Asia Research Labs in Taiwan and China?

Research in Corning has several missions: people and safety come first, be the best in the world in critical technology areas, deliver new technologies to the businesses, and inspire and enable our people to invent the future. The questions faced by each location tend to be the same: How do we preserve a balance between the need to deliver innovations quickly (like Ceramic Shield) and the need to maintain our deep level of expertise that can be leveraged to new problems?

We accomplish this in many ways. We must continue to publish in peer-reviewed journals, attend and lead conferences (such as those offered by ACS), and maintain a vigorous portfolio of new and interesting spaces. We must also adopt new tools to help us do our work, such as growing our Materials Informatics capabilities.

It’s also essential that we continue to connect with local universities and institutions to maintain a pipeline of qualified employees and support academic work in areas of interest. For example, Corning recently donated $5.5M to North Carolina A&T to support students in the Colleges of Education, Engineering, Science and Technology, and the Willie A. Deese College of Business and Economics.

What non-technical skills do you most highly value in your scientists?

Science is, at its core, a creative endeavor. One of my favorite quotes is from Dr. Mae Jamison, who said, “The arts and sciences are avatars of human creativity.” People who can keep two disparate thoughts in their mind at the same time, and work across disciplines, tend to be very creative in solving problems and coming up with new ideas. Therefore, individuals who make an effort to build a network of diverse connections and are open to learning new things will find a way to leverage those connections or knowledge in a new and interesting way.

Karen LaMonte, a fabulous glass artist, talked about learning, reading, studying, and how it all seeded ideas in her brain that – all of a sudden – would pour out of her like water released from a cloud. We value scientists (and engineers and technicians) who are open, collaborative, engaging, always learning, and open to new ways of doing things.

How has your family influenced your leadership style?

My father served in the US Army for many years. From Dad I learned service, dedication, and “taking care of the troops”. My mother loved the lifestyle of moving every few years; in fact, she would rearrange the furniture if we stayed in any one place too long! From Mom, I learned to try new things, talk to anybody about anything to make a connection, and to “just get out there and do it”.

My brother was a constant in my life, and we had a pretty typical sibling rivalry relationship. Navigating through that, I learned to appreciate the other person’s perspective and look for common ground. These attributes are directly applied to helping the team deliver technology. I work hard to deliver for them – whether it’s a strategy to follow, resources they need, coaching to adjust performance or behavior, rewards and recognitions for jobs well-done – and in response, they work hard to deliver for the company.

Now I have my own family. From my husband I learned the importance of really open communication. We can’t know what’s in each other’s head, even if it seems like what’s in our head should be obvious to the other. As leaders, we can’t over-communicate. People crave information and need it in order to be successful.

We have two children, one who has a global developmental disability and one who is very much on the bright side. Our younger daughter can make leaps of inference. We just give her hints and she quickly gets to the next step on her own and feels proud of her accomplishment and that we don’t need to spell it out for her.

Conversely, our older daughter needs extremely explicit instructions but absolutely wants to learn and grow and progress. Although it might have been easier for us to zip her jacket or load the dishwasher, we work hard to break down the tasks into manageable steps and teach her each component so that she can achieve them. A leadership challenge is figuring out which people need the barest of hints, and which people need explicit instruction. Both can be successful; they just take different strategies to help them achieve that next level.

Corning was founded in 1851. Since then, countless numbers of great companies have come and gone. What is Corning’s secret to surviving over that period of time, let alone prospering?

Corning is constantly reinventing ourselves. In the beginning we were a specialty glass company, then we became a television and consumer ware company. With optical fiber, we became a telecommunications company. After the telecom bubble burst, we became a television company again with our Display Technology business. We also learned that it’s better to have multiple businesses so that if one is on a down-swing, another can be on an up-swing.

Being open to new business ideas and new materials is key for us. In fact, we have groups of people whose role is to look for those new ideas and keep us at the forefront of new technology trends that can turn into new businesses. We maintain our core competencies in optical physics, ceramic science, and glass science and leverage our various manufacturing platforms to create new market access platforms and new business opportunities.

In an article published on February 12, 2021, Barron’s reported that Corning’s fastest-growing business is likely to come from cars. What applications does Corning have in mind for the automotive market?

Corning has two existing businesses in the automotive space: emissions control and automotive glass technologies. We invented the ceramic substrates at the heart of the catalytic converter and are pioneers in particulate filters for vehicle exhaust. Together, these components form the core of world-class emissions control systems in passenger cars, including hybrids, and heavy-duty trucks and machinery, helping significantly reduce exhaust emissions that impact air quality.

We are also enhancing vehicle exteriors and interiors with innovations in automotive glass technology that enable lightweight, damage-resistant windows and displays. Meanwhile, we recently completed a multi-year study of all the potential ways we can participate in the upcoming vehicle revolution, whether it’s autonomy, electrification, connectivity, or shared, which includes materials to enable all kinds of sensors on vehicles for autonomous driving, technologies to handle all the data required for autonomous driving, as well as materials for next generation batteries.

In auto glass, our AutoGrade™ Gorilla Glass and ColdForm™ Technology continue to address auto interior design needs at an affordable cost, as the market shifts to larger, longer, and shaped display areas.

Which do you expect will be more significant: The advances in materials science over the last 15 years, or the next 15 years? Please explain.

I will always be a technology optimist. The future will definitely hold more advances than the past. A few years ago, I read “Physics of the Impossible” by Michio Kaku. He classified problems as to whether we understand the physics or not, and whether we do or do not yet have the tools required to find a solution. Most of the cases he reviewed required a materials invention to enable that particular technology. I truly think that what was once impossible becomes possible due to new advancements and new tools.

Along those same lines is David Deutsch’s “Beginning of Infinity,” which argues that information, technology, and creativity are advancing at increasingly rapid speeds. When I started at Corning, we had two types of glass that had different levels of UV light transmission, but both were the same composition according to our state-of-the-art characterization. In less than 5 years, characterization had advanced such that we could tell one glass had 2 ppb alkali while the other had 4 ppb, and that made the difference.

Every time we buy a new transmission electron microscope (TEM), it’s quickly out of date. Fifteen years ago, one of our scientists in France learned of a new tool called tomography. We now use this technology in some of our factories. Now, we are very focused on doing everything we can in Materials Informatics – the collection, curation, and consumption of all of our data. We have huge stores of data and are working hard to leverage it to its fullest capacity. In fact, we’ve already been able to reduce time, cost, and risk with some of our glass composition work. Within 15 years, we’ll be reminiscing about how tedious the data collection and analysis process used to be.

What’s your view regarding material research versus process research, and the value of process inventions in scaling new materials?

Materials and process research are inseparable. There are few materials that are route-agnostic. In general, the chemistry of glass happens before any shape is applied; but in ceramics, we shape first and then the chemistry happens during the sintering process. However, that’s a pretty gross generalization, and the specific attributes of glass for any application are very process dependent. New materials are enabled by new processes, and new processes allow us to consider new materials.

If you look at our strategy and capital allocation framework, we are best-in-the-world in three core technologies, four manufacturing and engineering platforms, and five market-access platforms. Our M&E platforms are essential to our success. We invest in innovative machine design coupled with world-class process engineers and measurement scientists. Our factories are filled with process equipment invented, designed, and built by Corning. This dual focus, on both materials and process, has enabled our long-term success.

What is Corning doing to invest in the circular economy – the practice of ‘reusing, repairing and recycling instead of making things, using them, and throwing them away’ – as Barron’s put it in an article published on February 9, 2021?

We have several fronts that will enable a circular economy in our markets. Of course, our investment in clean air via our Environmental Technologies business is an early component of sustainability for the planet.

In terms of “reuse” on the research end, we are using some of our materials as cullet. In glass melting, cullet helps to stabilize the process from any raw material variability.

In addition, Corning was recently named a 2021 ENERGY STAR® Partner of the Year – Sustained Excellence recipient by the U.S. Environmental Protection Agency (EPA) for continued commitment to energy efficiency. This is the eighth year in a row that we have been named Partner of the Year, a fact that we take great pride in.

In 2020, we announced 12 global corporate sustainability goals, three of which highlighted our environmental commitments to energy, water, and waste management. We launched our Global Energy Management program in 2006 to create and execute effective energy strategies. The program has grown to include teams that implement energy- and water-savings projects at Corning facilities worldwide. Corning has a strong commitment to sustainability, and I think you’ll continue to see more and more companies talk about this, GHG reduction, recycling, and reuse; all of which will be required for a truly circular economy.

In February 2020, you returned to your alma mater, Alfred University, to give a presentation on “Women in STEAM Fields.” What were some of the key messages you delivered?

Most of us are probably more familiar with STEM than STEAM, in which the A represents Arts. I prefer STEAM because it’s at the intersections of disciplines that create new things. One way to think about data science could be that it overlaps math and science; perhaps design intersects art and science. I wanted to talk about opening-up STEAM to more people.

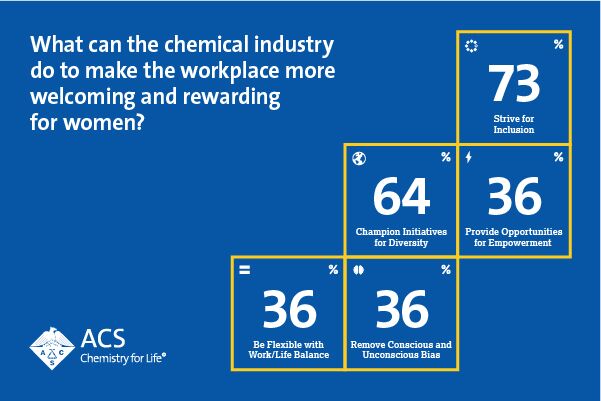

I’ve been made aware over the years of my own privilege and I feel obligated to use that privilege to elevate the voices of others. I wanted to communicate that although we’ve come far in many places, we have not achieved parity in outcomes for gay, cis-, or trans-women of any color. I hope I was able to open-up some conversations about the causes of disparity in outcomes and how they can be addressed.

Although young kids start on STEAM paths evenly, the outcomes are so much different for girls of all stripes. Why is that? I really believe in the research that shows our brains are wired to make decisions quickly, which makes it too easy to buy into stereotypes about people. We must actively question our own judgment when we “other” somebody. We all have biases and if we can acknowledge those biases, we can prevent them from impeding our decision-making around that person’s ability to do the job.

Through soliciting feedback from trusted colleagues, I understand that I have my own biases, whether conscious or unconscious, and I encourage others to also think about the biases they may possess. We need to consistently and actively work against these reactions in order to achieve parity in outcomes. I understand that I need to keep my instincts in-check and focus on helping all people move forward. I want others to also think about their own biases and how we can actively work against them in order to achieve parity in outcomes.

What motivated you to serve on the Alfred University’s Board of Trustees? And what are some of the biggest issues confronting the university?

My experience at Alfred was transformational. Due to both the small size and breadth of offerings, the community is very diverse. My social circle spanned engineers, artists, business majors, ROTC, sports, and more. Because it was a university, I was able to take classes in any of the colleges and I learned to live a whole life, not just my work life.

At Alfred, there were many faculty and staff who worked to make personal connections with students and help any individual with any kind of a problem. Also, the University has always been exceptional at hands-on training across fields. People leave Alfred with a strong set of practical skills.

The issues confronting the university are universal – students have a lot of choices these days and expectations of their living environments are higher. The university leadership is focused on providing experiences that are “Outside of Ordinary”, drawing on our maker culture history (which encourages creativity, pushing students to unlock their potential and reach their goals through an immersive, hands-on learning environment), as well as our long history of inclusion. I am very grateful to be able to serve the university in this capacity.

Does Corning offer a company discount on Apple products? Can you make me an honorary employee so I can get in on that?

We would love to have you on board! Corning offers a great set of perks and benefits to employees. I would encourage you to join our team to learn more.

Christine E. Heckle, PhD, was appointed research director, Inorganic Materials Research and Asia Research Labs, in December 2017. In this role, Heckle is responsible for setting the strategies for materials research in Corning, also recently including New Materials and Processes function, and for CRCT & CRCC in their contributions to the corporation. Heckle is the champion for the Materials Informatics effort to enable data-driven materials discovery and is an important component in Corning’s shift toward a data culture.

Previously, she was research director, Crystalline Materials Research, where she led the development of new ceramic products to support the Environmental Technologies and Specialty Materials segments, as well as new business and exploratory arenas.

Heckle joined Corning in 1997 in Corning Specialty Materials development, contributing to HPFS product and process developments. She moved to Environmental Technologies development and subsequently commercial technology to lead a variety of programs that introduced new products into the marketplace. Under her leadership, DuraTrap® AT was expanded into the heavy-duty market, and two new product offerings were launched for the light-duty market.

Heckle is a member of SPECTRA and ADAPT; she mentors and coaches widely. She won the 2018 S&T People Development Award – Manager. Heckle serves as a member of the board of trustees for Alfred University in Alfred, New York. She holds a Ph.D. in glass science from Alfred University.

This article has been edited for length and clarity. The opinions expressed in this article are the author's own and do not necessarily reflect the view of their employer or the American Chemical Society.

Copyright 2022 American Chemical Society (All Rights Reserved)