Key Takeaways:

- Technology trends and how it may affect Serban's team of scientists

- How Serban develops international markets while protecting the intellectual property of Air Liquide

- Serban opens up about his biggest challenges and how he addresses them

Several Boss Talk participants have paired a PhD in chemistry - or some other science - along with an MBA. Has the MBA made you more effective in your current role as VP, R&D, Americas? If so, how?

I truly feel that my MBA has enabled me to be more effective in my current role. I completed my MBA over a two-year course, as I was finishing my last year of Ph.D. and starting my first R&D position with Air Liquide, during which time I explored topics such as marketing and finance and business models.

Although not all the tools I learned during my MBA were applicable, it did make me more effective as it opened my eyes to the users’ perspective and made me think less about technology and more about offers and value creation. In addition, the business-focused background allowed for easier transitions into more operational and management positions, which now helps me better understand my internal customers’ needs.

What technology trends are you following most closely with an eye toward how they may impact the work of your scientists?

The major trends that we are following are the energy transition (with a focus on climate change and CO2 emissions), the change in demographics (with a focus on the global aging of the population and the urban transformation), as well as the digital transformation. Particularly the last one has a clear impact on the way work has changed to become more collaborative and more agile.

How does your company develop international markets while simultaneously protecting Air Liquide’s intellectual property?

There are many layers of protection that allow our group to expand internationally while simultaneously protecting its IP.

Firstly, there is an intrinsic protective element in the way the industrial gas industry operates, as most gases are consumed locally in the same countries where they are being produced, very often no more than a few miles away from the production site or its pipelines. So, most industrial gases sold in the US are being produced in the US, by plants built in the US, using IP protected in the US. The same is true for most other countries in which the group operates, be it in Europe, Africa or Asia.

Secondly, the group's business model, which is to design, build, own and operate its industrial gas plants as well as own and operate its fill centers and logistics fleets facilitates a good level of control over the use of many IP protected technologies, which are used internally for gas production and distribution.

Thirdly, most of our business is B2B, done with reputable companies that care about regulatory and legal compliance and is covered by long term agreements that protect each party’s IP.

And last but not least, since Air Liquide was created through a disruptive technology and has continuously grown since through innovation, every single one of its employees understands the importance of protecting the technologies that are core to our differentiation on the market and fundamental to our future.

How did your parents influence your leadership style?

Many people that I have interacted with during my professional career have influenced my leadership style and I hold them in high esteem for their counsels and for their role models.

However, it is true that the foundation of leadership rests on values learned early in life. To a large extent my parents taught me to care about others, to respect the value of honor, the importance of truth, to be strong in hard times and self-confident, but at the same time to be humble and learn from my mistakes. I have tried to thank them by teaching the same values to my own children.

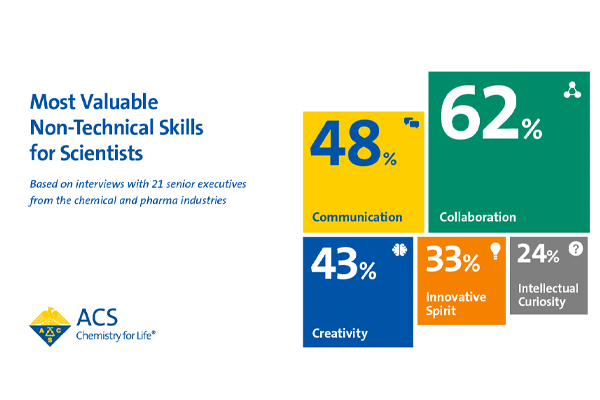

What non-technical skills do you most highly value among scientists working at Air Liquide?

I value their creativity, their out-of-the box thinking, their skills to communicate well internally and externally, their team working spirit, as well as their capacity to constantly adapt to new topics and environments. Last but not least, I should mention the customer and patient focus, that drives everyone’s passion at Air Liquide and fuels our engagement.

What’s the biggest challenge you face in your job? What is your basic strategy for addressing it?

As with any R&D team within an organization, there is an expectation not only to deliver new patented technologies that will improve its competitive advantage and fuel profitable growth, but also that we provide a constant stream of talented people to become tomorrow’s leaders, as well as provide expert advice on many technical topics.

With that, one of the biggest challenges is obviously centered on people, on our attractiveness toward the millennials, on our capacity to retain them and help them grow in their careers, on the way we manage our wealth of know-how and its transfer to the next generation.

To overcome this challenge, we start by selecting candidates that have a strong technical and cultural fit with the organization, with a desire to learn, grow, and have a long-term career with our group. Then we need to integrate them within our teams and keep them engaged by providing them with meaningful projects and with opportunities to interact with their colleagues all over the world.

Since 2000, you have been posted to France, the United States, Canada, Tunisia, and Japan. Professionally, what are the pros and cons of such geographic rotations?

Personally, I find it exciting and enriching to discover new geographies, new people, new languages, new cultures and new ways of doing business. Such changes force you to challenge any of your preconceived ideas, keep an open mind, develop your listening skills and they keep you on top of your game in a changing environment.

On the flip-side, international rotations also mean you are far from your family and friends, your children have to change schools every 3 years and lose contact with their friends, and it can be difficult for your partner to manage his/her career in parallel. As you and your family transform and become “citizens of the world,” part of your initial culture and comfort zone gets “lost in translation”. Nevertheless, looking back at my past 15 years on three continents, I am convinced that the benefits far outweigh the costs and I would definitely do it again.

Apart from Air Liquide, what companies do you most admire, and why?

In general, I admire companies that create smart products that make your life easier. Apple, Amazon and Google are good examples, as I use their products and services daily. But if I have to choose one that I most admire, it would be DeepMind, the creators of AlphaGo. As someone who has played GO for the past 35 years, I find their AlphaGo AI accomplishment both shocking and admirable. I am convinced that the benefits of specialized, deep learning AI programs, like the one DeepMind has created, will have a momentous impact on our life and our civilization.

It might come as a surprise for many ACS Industry Matters readers to learn that Air Liquide has designed and installed over 120 hydrogen-fueling stations worldwide, which supply energy for Fuel Cell Electric Vehicles (FCEVs). What changes to the supply chain were needed to transition from delivering lab quantities of hydrogen to supplying these fueling stations?

Every generation, Air Liquide develops or enters a new market, starting with welding and cutting in the 20’s, then moving to large industries as steelmaking and petrochemical industries developed in the 40’s, to healthcare in the 60’s and electronics in the 90’s. Hydrogen energy is the new frontier that has been emerging for the past decade, and Air Liquide, as most of the industrial gas companies around the world, is building and operating the infrastructure for fueling the cars of tomorrow.

But the needed change for adaptation is not to upsize lab-scale hydrogen production. Air Liquide has been producing hydrogen on an industrial scale for more than 35 years, supplying millions of cubic feet of H2 every day to petrochemical, glass, heat treatment and food companies. The key challenge for the mobility market is to efficiently supply relatively small quantities of hydrogen (no more than 5kg for a full car tank) over a wide territorial footprint (i.e. everywhere in the US) and through production and logistics means that have low CO2 emissions to the atmosphere.

To achieve this sustainable ambition, we are not converting our existing industrial H2 to the new market; instead, we are investing in a mix of wholly new low-carbon production methods. And the supply chain solutions that will be implemented in highly constrained California, in low-cost gas and wind power rich Texas or in energy-challenged Northeast will not be the same.

Best guess: In what year would you expect the number of FCEVs on the road in the United States to overtake combustion engine models?

The move away from CFCs, the transition from the light bulb to LED lighting, and the mobile phone and internet revolution proved that once the technology is ready and the political decision has been taken, the complete industrial transformation could be done in 15 years.

No one knows how long it will take for cars, but as cities and countries choose to move away from combustion vehicles (as an example Paris banned all diesel engines within the city walls by 2024 and all combustion engines by 2030) the move to electric vehicles, whether battery powered or fuel cell powered, will only accelerate. And I imagine that sometime between 2030 and 2040 there will no longer be any financial or performance incentives for consumers to buy combustion engine powered cars. So my personal expectation is that we’ll see battery and fuel cell electric vehicles overtake the numbers of the combustion engine cars on the roads well before 2050. And by that time the cars will probably be self-driving anyway…

Serban Cantacuzene began his role as VP R&D Americas in September 2018. His focus is on defining the R&D vision in the Americas, managing R&D teams of researchers at the Delaware Research & Technology Center and in the Americas, building stronger ties with the American innovation ecosystem (comprised of venture capitalists, start-ups, and academia within the dynamic high-tech and clean energy sectors), as well as supporting the business activities of the various Air Liquide entities located in the Americas zone, such as Airgas.

Serban has 23 years of experience with the Air Liquide Group in Europe, Asia, Africa, Canada, and the USA. He joined Air Liquide in 1995 in the Paris Saclay Research Center to work primarily on Heat treatment and metallurgy. From there, Serban spent 17 years in various operational positions in Air Liquide, first in the Paris Head Office then in USA, Canada, Tunisia and most recently as Executive VP and COO of Air Liquide Japan.

Serban holds a Master of Engineering in Material Science from Grenoble's National Polytechnic Institute, a Master in Business Administration from IAE Paris and a Ph.D. in Physics from the CEA and the University of Paris XI (France). His experience includes: Research (7 Patents), Marketing, Planning and Operations control, Management of change and General Management.

This article has been edited for length and clarity. The opinions expressed in this article are the author's own and do not necessarily reflect the view of their employer or the American Chemical Society.

Copyright 2019 American Chemical Society (All Rights Reserved)