By: Nina Notman

In November 2019, Eastman Chemical Company announced that it was going to start recycling old polyester carpets from homes and businesses. The firm will use the reclaimed polymer building blocks to make products such as textiles, cosmetics, personal care and ophthalmics.

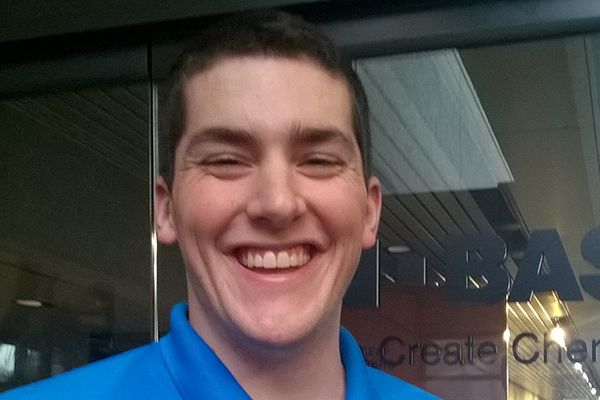

Eastman is now expanding its chemical recycling operations to include a host of post- and pre-consumer waste materials. “We’re taking waste streams that don’t currently have a good end-of-life solution and converting them into high-performance materials while ensuring the process is worthwhile commercially,” explains Jim Goetz, polymer applications research scientist for the global specialty chemical company.

Goetz joined Eastman in 2014, following an undergraduate degree in plastics engineering technology at Penn State Behrend and a PhD in polymer science (with a focus on breathable plastic membranes for clothing) in Sergei Nazarenko’s group at the University of Southern Mississippi.

His current focus is developing processes to turn waste materials into sustainable copolyesters for high-performance applications. “My time is largely split between planning experiments in the office and running lab scale experiments,” says Goetz. However, “I also work with our operations team to implement new strategies developed in the lab on the manufacturing floor.”

Goetz describes himself as “very process minded.” A couple of years ago, he and some Eastman colleagues decided to utilize their process-chemistry skills outside of the lab in home brewing. As production volumes increased, the scientists set-up a nano-brewery. Bays Mountain Brewing Company opened in Kingsport, TN, in March 2019.

“There are a lot of similarities between brewing beer and what I do in the lab every day, developing the tools to make the processes more efficient and ultimately produce a better product,” Goetz explains. The nano-brewery is also enabling him to develop new skills: “I like to call this my in-situ MBA as I am learning the ins and outs of running a business.”

What’s the best part of your job?

Finding new ways to progress the technology behind material science, and also working with teams that are energized to solve problems.

What’s the most interesting project you’ve worked on?

An early project of mine at Eastman, where I rapidly developed a new material from starting monomers all the way through to manufacturing scale. We went from hundred-gram samples to hundreds or thousands of pounds an hour, all within a year.

What’s in your lab coat pocket?

Sample bags and sharpie markers.

What’s your scientific obsession?

Polymer physics. If I have a few minutes, I pull a polymer physics book off my shelf and just randomly read a page.

What’s your favourite laboratory instrument?

A twin screw extruder. For compounded products, it’s how we add additives or mix multiple materials together.

What is your morning routine?

Wake up, shower, eat breakfast, walk the dog, make coffee and go to work.

Music or no music in the lab? If so, what do you like to listen to?

My office is definitely a music zone. The lab not so much. I like everything from hip hop to country.

How do you deal with stress?

Bicycling – mountain biking and road biking.

And hidden talents?

I can ride a unicycle.

What’s your favourite beer?

A Belgian blonde.

Nina Notman is a freelancer, based in the UK. This interview was edited for length and clarity.