FOR IMMEDIATE RELEASE

“Application and Properties of Co2+-Doped BaAl2Si2O8 Blue Pigments in Glazes”

ACS Applied Optical Materials

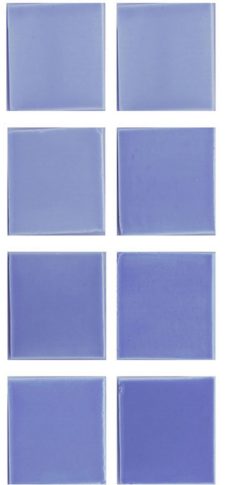

Whether ultramarine, cerulean, Egyptian or cobalt, blue pigments have colored artworks for centuries. Now, seemingly out of the blue, scientists have discovered a new blue pigment that uses less cobalt but still maintains a brilliant shine. Though something like this might only happen once in a blue moon, the cobalt-doped barium aluminosilicate colorant described in ACS Applied Optical Materials withstands the high temperatures found in a kiln and provides a bright color to glazed tiles.

Many of the brilliant blue pigments — like those in antique Chinese porcelain or works by Claude Monet — make use of cobalt-based compounds, including the famous “cobalt blue.” Though the metal itself is toxic, in mineral form it has high chemical and thermal stability, and those properties make cobalt aluminate one of the only pigments suitable for high-temperature applications, including pottery glazes. Today, cobalt is used in lithium-ion batteries, and demand for the metal ore will likely increase as the need for battery power grows. As a result, scientists including Peng Jiang and colleagues are searching for alternative pigments that require fewer cobalt ions and still maintain a bright blue hue.

The team based their new pigment off a barium feldspar mineral (BaAl2Si2O8) that also features high temperature and chemical stability. Compounds containing barium, aluminum, silicon and cobalt were ground together, pressed into a sheet, then heated to above 2550 degrees Fahrenheit to form the pigment. Then the researchers mixed the powder into a ceramic glaze, sprayed it onto tiles and fired them to produce glazed pieces of pottery. The pigment was stable at temperatures up to 3200 degrees — well above the typical firing temperature of a pottery kiln — and only experienced slight color changes when exposed to either acidic or alkaline solutions, demonstrating the compound’s stability. Tiles sprayed with the pigmented glaze maintained a smooth, bright surface that deepened in color as the concentration of cobalt in the pigment increased. The researchers say that this new powder substantially reduces the amount of cobalt needed, resulting in a cheaper, easier-to-produce blue ceramic pigment.

The authors acknowledge funding from the Beijing Nova Program, the Fundamental Research Funds for the Central Universities, the Youth Teacher International Exchange & Growth Program, and the National Science Foundation.

###

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and all its people. The Society is a global leader in promoting excellence in science education and providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a leader in scientific information solutions, its CAS division partners with global innovators to accelerate breakthroughs by curating, connecting and analyzing the world’s scientific knowledge. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive press releases from the American Chemical Society, contact newsroom@acs.org.

Note: ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies.