The conventional wisdom in water treatment is that implementing water solutions that improve sustainability come at a high cost. That there is constant tension between sustainability benefits and low cost. That you can’t have them both at the same time—something is always a trade-off.

Our DuPont team has found that this does not have to be the case. We can pursue a world of “and” where the most sustainable solution can also be the most cost-effective when considering next best alternatives.

Our purpose to empower the world with the essential innovations to thrive is supported by our sustainability strategy and 2030 Sustainability Goals. At DuPont, we look at sustainability through an innovation lens, which challenges us to apply science and technology against the complex challenges facing our world such as water scarcity.

DuPont Water Solutions (DWS), part of DuPont’s Safety & Construction business, is a leader in water purification and separation technologies, including ultrafiltration, reverse osmosis (RO) membranes, ion exchange resins (IER) and biological water treatment solutions such as membrane bioreactors (MBR) and membrane aerated bioreactors (MABR).

The water team includes more than 2,400 employees around the world working with a shared purpose to solve global water challenges for the purification, conservation and reuse of water.

Unfortunately, not every person (663 million are still without access to clean drinking water) and industry can access clean, safe water, as only 2.5 percent of the earth’s water is fresh. With more people, more industry, depleting resources, pollution and climate change, the pressure on water supplies continues to intensify.

As the world solves United Nations Sustainable Development Goal #6 for Clean Water and Sanitation, we unlock numerous interconnected challenges preventing humans from thriving—from health and well-being to gender equality and education.

The team at DuPont is optimistic—our technologies are today enabling water scarce regions to achieve water security and resiliency. Through work with customers and community partners, DuPont is breaking traditional thinking preventing humanity from tapping all water resources, including what we traditionally consider “waste water.”

If you consider both sustainability benefits and cost benefits, there is an intersection where a solution can yield both at the same time. This is the area of optimization where solutions maximize water savings and minimize total life cycle cost.

Realizing Water Sustainability

DuPont is focused on the optimized solution space, which minimizes the total lifecycle of water. We can think of this as follows:

Total lifecycle of water = cost of freshwater + cost of discharge + cost of raw materials

The goal for our customers is to minimize the cost of freshwater, minimize the cost of discharge and minimize the cost of virgin raw materials. We can minimize the cost of freshwater through recycling water within an industrial process, reducing the need for fresh water. We can minimize the cost of discharge by reducing the volume of waste and we can reduce the cost of raw materials if we can recover them through the process of recycling water. When we do this, our customers maximize sustainability benefits such as: reduced pull on scarce freshwater resources, reduced use of virgin raw materials and less volume of sludge for disposal.

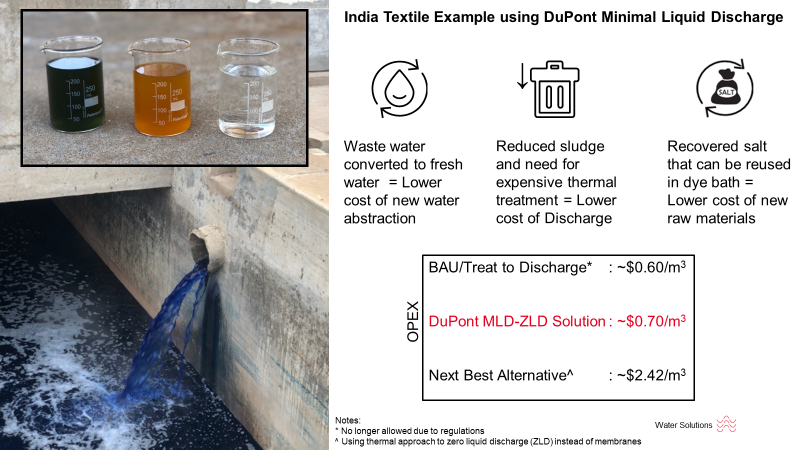

A good example of how this plays out is in Chennai, India where many textile dyeing plants operate with razor-thin margins. The graphic below shows three types of water. The picture on the left is the raw wastewater with the deep indigo color required for the textile dying processes. The beaker in the middle shows the salty brine extracted from this wastewater, and finally the recovered clean clear water appears in far-right beaker. Textile plants in this region had no choice but to reduce their wastewater discharge as the salt level of this water was starting to impact the yield of nearby crops.

Our water team put together a technology stack for the Chennai dying plants that included the DWS fouling resistant membrane line, FilmTec™ Fortilife™, as well as its nanofiltration line that allowed for salt extraction, which was critical to the textile manufacturers’ ability to extract and reuse the dye salt.

The cost calculations show that the minimal liquid discharge (MLD) and recycle system that DuPont put in place is roughly three times less expensive than the next best alternative, which required brute force, high thermal energy processes. The status quo method, which was to discharge the wastewater, was no longer viable and going from $0.60 per m3 of water to $0.70 per m3 of water maintains the health of these textile businesses, and in turn, the livelihoods of the textile plant workers and nearby community.

India Textile Example using DuPont Minimal Liquid Discharge

This is one of many examples that brings to life the idea of “and.” Economic benefits and sustainability benefits. Business benefits and community benefits. We just need to think a bit creatively and apply the technologies available to us.

The bottom line is that fresh water supplies are under pressure almost everywhere, and with more people, more industry, depleting resources, pollution, and climate change, the pressure on water supplies and our environment will continue to intensify.

Our mission at DuPont is to empower the world with essential innovations to thrive, but just like water, we also must change, expand and grow. We believe that a very different water future exists. A future where water is accessible, abundant, adaptable and affordable to all – where waste becomes a resource and even water-scarce regions can achieve water security and resiliency. Best of all, the technologies to support this water optimized future are here today and are already being used by people all over the world. DuPont is committed to leading an unconventional approach to water that breaks traditional thinking and behaviors, so the world can tap into all water resources, close loops to build resilient infrastructure and create a water optimized world where all people can thrive.

This article has been edited for length and clarity. The opinions expressed in this article are the author's own and do not necessarily reflect the view of their employer or the American Chemical Society.

Copyright 2022 American Chemical Society (All Rights Reserved)