In 2007, Chris Noble left a high-paying banking job in New York City to pursue a master’s degree in business administration. He was 25 at the time. His motivation for doing so was to join Noblehurst Farms, the corn, wheat, and dairy cow operation in rural Pavilion, New York, that had been in his family for generations.

The first of Noble’s family to work the land was a soldier who moved to western New York after the Revolutionary War. The farm produced enough vegetables and dairy products to feed his family and neighbors. Over several generations, the farm expanded to its current size of 1,800 Holstein cows and 2,500 acres, or about 4 square miles.

The family’s deep connection to the land and the opportunity to lead the farm’s environmental efforts lured Noble back home.

Unlike his forebear’s experience, when Noble joined the farm, the threat of climate change was—and still is—looming. As part of the agricultural industry, which releases greenhouse gases—heat-absorbing gases in the Earth’s atmosphere—he had a chance to do something about it.

How 'Green' is Biogas?

If burning biogas, which is methane from organic waste, produces CO2, how does that help the planet?

It might seem counterintuitive, but burning biogas—although it releases CO2—is considered carbon neutral. This is because the amount of CO2 that’s released from burning biogas is no more than what went into the organic matter in the first place. Releasing methane instead of burning it, on the other hand, would result in putting a more potent greenhouse gas in the atmosphere than CO2.

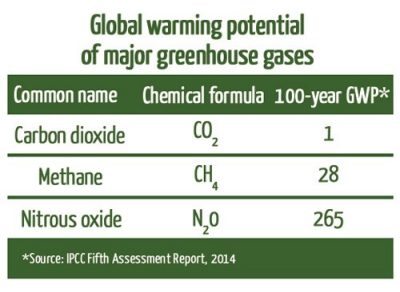

Methane has a much higher global warming potential (GWP) than carbon dioxide. A greenhouse gas’s GWP is its ability to trap extra heat in the atmosphere over time compared to CO2. For example, the 100-year GWP of methane is 28. So, if 1 ton of methane were released into the atmosphere, it would create the same amount of warming over 100 years as 28 tons of CO2.

Citing new research, Frank Mitloehner, a professor of air quality at the UC Davis, says that harnessing and using biogas as fast as it’s generated on a large scale has the potential to make a difference in global warming.

Cow emissions

Dairy farms and livestock operations are valuable food sources, but they are also large methane producers.

According to the U.S. Environmental Protection Agency (EPA), the two industries account for about 10% of all methane (CH4) that’s released into the atmosphere from human activities in the United States.

Methane makes up about 16% of all greenhouse gases. These gases, which occur in trace amounts in the atmosphere, don’t actually work like a greenhouse. Actual greenhouses have windows that allow warming rays from the sun into the structure, and prevent warm air from leaving. Greenhouse gases, however, absorb infrared radiation from the sun-warmed surface of the planet. These gases then transfer the absorbed energy to surrounding atmospheric gases via bond vibrations. This increases the average thermal energy and raises the temperature.

“Greenhouse gases are like a big blanket that covers the earth,” says Frank Mitloehner, a professor of air quality at the University of California (UC), Davis. “The Earth needs some of those to keep the planet warm enough to live on.”

But human activities, including dairy farming, emit these gases into the atmosphere in increasing amounts, and the atmosphere becomes warmer.

Cows release methane from both ends: by burping and through their manure. Cows, like other ruminants including sheep, goats, and giraffes, have four stomach chambers. As the animals eat a mixture of hay, grass, and grains, microbes in one of the chambers, the rumen, process the food. During this process, called enteric fermentation, methane is created—and released through belches.

Methane production from cow poop is actually an unintended consequence of waste-management practices. Decades ago, dairy farms kept small herds and spread manure on fields as a natural fertilizer at about the same pace the cows produced it. But as herds grew into the thousands, farmers built and covered storage pits to hold the manure.

“When the industry changed from spreading manure daily to storing it in a container, it encouraged methane production through anaerobic digestion. That methane is released into the atmosphere,” says Peter Wright, an agricultural engineer at Cornell University.

Anaerobic digestion is the process by which organic material, such as manure, is broken down in the absence of oxygen (O2).

Waste not, want not

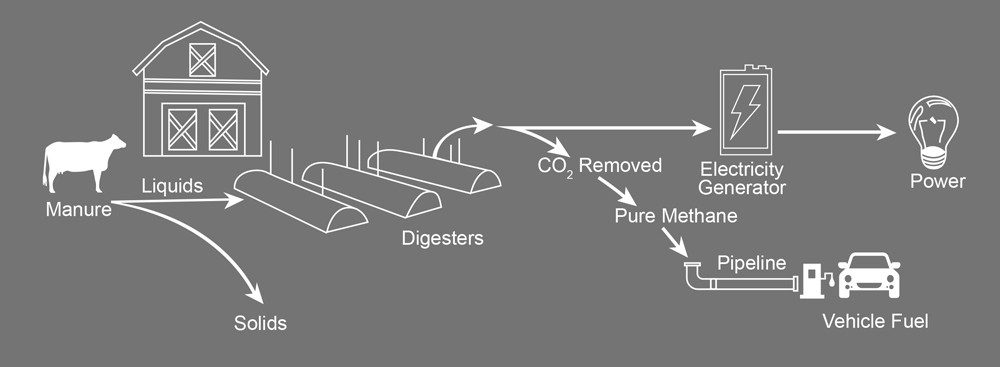

Now, rather than letting the methane from manure escape into the air, dairy farmers can harness the gas by trapping it in human-made anaerobic digesters. An anaerobic digester is like a cow’s stomach on an industrial scale—it’s an oxygen-free environment where biological processes break down organic matter.

The size and shape of digesters vary. In California, they look like oversized football fields covered in black plastic. In New York, above-ground dome-shaped buildings are capped with flexible plastic coverings. These systems are maintained at the same temperature as a cow’s digestive system, between 37.8 °C (100 °F) and 40 °C (104 °F), creating an environment in which anaerobic microbes can thrive.

The process starts when the cows are fed. As they chew, the meal moves into their stomach, where microbes break down the food. The cow passes the digested food as manure, which is then pushed with a tractor or scooped up and driven to a digester.

Inside the digester, bacteria use biological catalysts called enzymes to break down the manure’s insoluble polymers, including cellulose, into smaller, soluble components. These smaller components, such as glucose, get broken down even further, and the gases CO2 and CH4 are produced.

The overall process can be described by the following reaction:

C6H12O6 → 3 CO2 + 3 CH4

Digesters capture the methane, preventing it from escaping into the atmosphere.

Burning the methane releases thermal energy, which turns a turbine and powers a generator.

CH4 + 2 O2 → CO2 + 2 H2O + energy

The farmers use the electricity generated from burning methane to power their farms, heat their homes, and if there’s any extra, sell it back to the power company.

The U.S. Department of Agriculture reports that about 37,000 dairy farms are in operation. About 200 of those farms are harnessing biogas from manure, according to the EPA. Other sources of biogas include hog and poultry farms, and wastewater treatment plants. The Environmental and Energy Study Institute reported in 2017 that the United States had 2,200 biogas systems, a fraction of the total number of potential systems the country could have.

A noble investment

Noblehurst Farms was an early adopter, installing its first anaerobic digester in the early 2000s. It was destroyed in a fire, and they replaced it in 2014.

“The digester was an example of something we could invest in on the farm that would help keep us cost-competitive, diversify our farm, and address climate change,” Noble says.

The current dome-shaped building holds more than 1 million gallons of liquid poop, which is separated from the solids. The plastic roof traps the gas naturally produced as bacteria digest the manure.

To supplement the 40,000 gallons of manure his cows excrete every day, Noble launched Natural Upcycling, a food scrap collection business. Food scraps also release methane when broken down.

The combination of manure and food scraps processed in Noblehurst’s digester reduces methane by an amount equivalent to reducing carbon dioxide emissions by an estimated 409 tons per month. That’s like taking 1,000 cars off the road annually, according to AgSTAR, a federal program that promotes biogas recovery from farms.

The resulting mixture of food waste and cow manure produces 200 to 250 cubic meters of biogas. That’s enough biogas to fuel a 500-kilowatt (kW) generator.

The 500-kW generator keeps the digester heated, and powers the farm, a neighboring creamery, and a cheese-making facility. The system saves the farm about $100,000 in electricity costs annually. As an added bonus, the digestion process removes the potent smell associated with manure.

Fueling change

In 2016, California passed a law requiring dairy farms to cut methane production by 40% by 2030. Methane digesters have helped farmers already achieve a 25% reduction in three years, according to Mitloehner. A patchwork of other state regulations also aims to cut methane emissions from various sources, including agriculture.

Many farmers are motivated by more than new laws to help with climate control. They are often called the original environmentalists for spreading manure from their own livestock to fertilize their fields, as opposed to buying synthetic or mined fertilizers, which require additional energy and resources to produce and transport. Consistent with that tradition of practical solutions, farms across the country, in addition to building anaerobic digesters, are implementing other practices to address climate change.

Noble notes that practices that help the planet also help farmers, which could allow generations-old operations like his to carry on well into the future.

REFERENCES

Biogas Potential in the United States. National Renewable Energy Laboratory, Oct 2013: https://www.nrel.gov/docs/fy14osti/60178.pdf [accessed Feb 2020].

Jacobs, J. P. Cow Manure: An Unexpected Climate Solution. E&E News | Greenwire, May 21, 2019: https://www.eenews.net/special_reports/recipe_for_change/stories/1060367345 [accessed Feb 2020].

Fact Sheet–Biogas: Converting Waste to Energy. Environmental and Energy Study Institute, Oct 3, 2017: https://www.eesi.org/papers/view/fact-sheet-biogasconverting-waste-to-energy [accessed Feb 2020].