FOR IMMEDIATE RELEASE

“Enhanced Thermal Conductivity of Nanodiamond Nanosheets/Polymer Nanofiber Composite Films by Uniaxial and Coaxial Electrospinning: Implications for Thermal Management of Nanodevices”

ACS Applied Nano Materials

As smart electronic devices become smaller and more powerful, they can generate a lot of heat, leading to slower processing times and sudden shutdowns. Now, in ACS Applied Nano Materials, researchers use an electrospinning approach to produce a new nanocomposite film. In tests, the film dissipated heat four times more efficiently than similar materials, showing that it could one day be used to keep electronics cool.

Smaller and smarter electronics have revolutionized many aspects of life, from communication to medicine. But shrinking sizes mean that these devices concentrate heat in smaller areas, which can cause lagging computing speeds and even force devices to completely shut down unexpectedly to prevent damage.

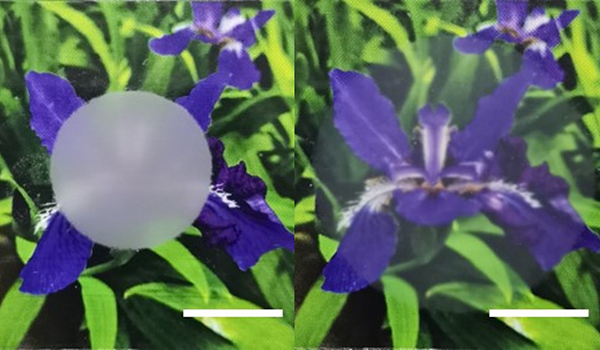

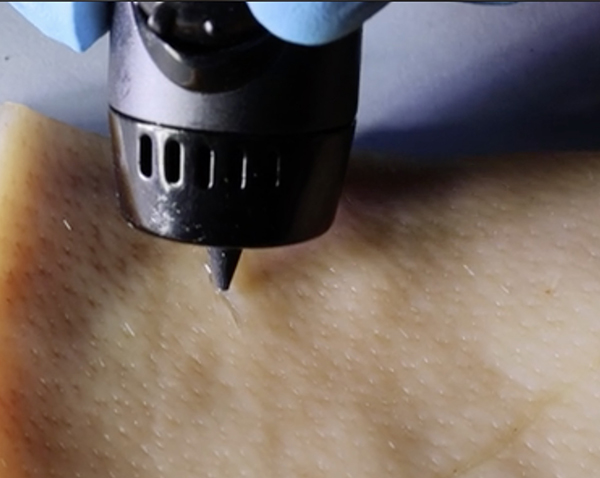

To dissipate this heat, researchers are turning to nanocomposite materials that contain a flexible polymer and thermally conductive filler. A simple way to make nanocomposites is by electrospinning, in which a solution of polymer and filler is jetted out of a syringe through an electrically charged nozzle, forming fibers that build up into a thin film. While simple, electrospinning from a single solution, or uniaxial electrospinning, makes it difficult to control the material’s properties. So, Jinhong Yu, Sharorong Lu and coworkers used a two-solution technique, called coaxial electrospinning, to better control the fiber design and improve heat dissipation of a new nanocomposite.

The researchers made one solution with their selected polymer, polyvinyl alcohol, and a separate solution with the thermally conductive filler, a nanodiamond material, to produce the new nanocomposite. By fitting a syringe of each solution onto a nozzle that combined the two, the researchers made fibers with a polyvinyl alcohol core and nanodiamond coating, rather than a random distribution of the two components. The researchers say the coated fibers act as a “highway” to direct heat, like traffic, along and across the fibers throughout the film. In tests, the new materials dissipated heat better than those made with the traditional nozzle and were four times as thermally conductive as previously reported nanocomposites. The researchers say that these films could one day be used to keep tiny electronics working hard while staying cool.

The authors acknowledge funding from the Key Laboratory of New Processing Technology for Nonferrous Metal & Materials and the Ministry of Education/Guangxi Key Laboratory of Optical and Electronic Materials and Devices.

###

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and all its people. The Society is a global leader in promoting excellence in science education and providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a leader in scientific information solutions, its CAS division partners with global innovators to accelerate breakthroughs by curating, connecting and analyzing the world’s scientific knowledge. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive press releases from the American Chemical Society, contact newsroom@acs.org.

Note: ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies.