What if, instead of trays of gooey pizza and wilted lettuce, the school cafeteria cranked out plates of food that were synced to your body’s nutritional needs for optimum performance for the rest of the school day? Perhaps on Tuesday, your personalized lunch would contain an extra jolt of caffeine to make up for a late night of studying; maybe on Friday you’d need a dose of creatine to help your muscles recover from a strenuous morning game of pickleball.

To achieve that level of culinary nimbleness, researchers at the U.S. Department of Defense are turning to an unusual appliance: a 3D printer. In the Food Engineering and Analysis Lab, located at an Army facility in Natick, Massachusetts, Lauren Oleksyk and her colleagues are creating 3D-printed bars tailored to optimize performance in specific scenarios or to address the needs of individual soldiers. Printers that create such supplementary rations could one day be synced with wearable sensors that detect a person’s physiological profile and nutritional needs in real time, Oleksyk says.

Three-dimensional printers deposit bits of materials—called filaments, which are usually made of plastic—through a nozzle onto a surface to build preprogrammed shapes layer by layer. The filaments need to flow through the nozzle and then fuse—melt and adhere together—to build the shape.

The plastics that are used, such as polylactic acid, become soft when heated and harden when cooled. They flow through the heated nozzle and solidify quickly when they hit the printing surface. To save on plastic, the inside of the shapes are often hollow, filled only enough to provide support.

Since the mid-1980s, manufacturers and home hobbyists alike have used 3D printers to make customized machine parts, medical implants, furniture, and even houses. Although 3D printing has touched many industries in the 40 years it has been around, the devices are in their infancy when it comes to printing food.

In the past decade, food scientists have been modifying the software and hardware normally used for sculpting plastic and putting it to work on printing concoctions of peanut butter and other ingredients. At the same time, they have been wrestling with how food that flows through the tubes of a 3D printer can be as tasty as the traditional stuff.

Playing With Food

The 3D technology can enable people to customize their food creations, and explore new culinary dimensions in their kitchens, making tastes and textures that have never been created before.

For example, Hod Lipson, a robotics engineer at Columbia University in New York City, and his team printed a seven-ingredient slice of cheesecake with an elaborate internal structure. Because of the ways they constructed the layers, biting into the cheesecake released the taste of each ingredient in waves, says Jonathan Blutinger, a graduate student in Lipson’s lab.

The novelty of 3D printing food would be even greater if researchers could figure out how to print and cook simultaneously, according to Lipson. Food 3D printers are mostly suited for producing intricate shapes and designs, not actually cooking the ingredients. “We spend such a lot of our lives making food,” he says. “We broil; we panfry. Except for microwaves, [today’s cooking] is all techniques that are thousands of years old.”

Lipson was among the first to explore 3D printing with food—and it wasn’t even on purpose. In the early 2000s, most 3D printers could print with only a single material at a time, but his team was trying to figure out how to print machine components, such as batteries or actuators, out of multiple materials.

To calibrate the printer for each material, Lipson’s students reached for food ingredients, such as cookie dough, cheese, and chocolate, which are easier to work with but have some of the same properties.

The food ingredients then “took on a life of their own,” Lipson says.

Initially, colleagues poked fun at the lab’s growing interest in food printing. But Lipson was drawn to the technological challenges. “I still have a hard time explaining this to my colleagues, but peanut butter is much more complicated [to work with] than aluminum,” he says. Its properties are not linear, and small fluctuations in temperature—even just a degree or two—completely changes how it flows.

How did Columbia Engineering print the cheesecake? Watch the video to find out.

Printable Edibles

For 3D printers to become common kitchen appliances, though, the technology needs to mature. The hardware is pretty simple, Blutinger explains, the device “can pick up a syringe of food and then shoot it out based on some kind of directed path.”

But there’s no standard software or hardware optimized for the specific challenges of printing food. “We’re using industry software designed for printing plastic and metal parts, and we have little hacks to make it work,” Blutinger says.

The field also needs to amass standardized digital recipes that home cooks could download and use in their 3D printers, similar to the designs makers can download for making plastic toys or tools.

To create a printable food, researchers must mix and remix ingredients to adjust material properties, such as viscosity, adhesion between the printed layers, and the rate at which different layers get deposited, all through trial and error.

But it is still food, so researchers must also attend to its nutritional content and palatability. Generally, for foods made with an extrusion printer, viscosity is an important factor.

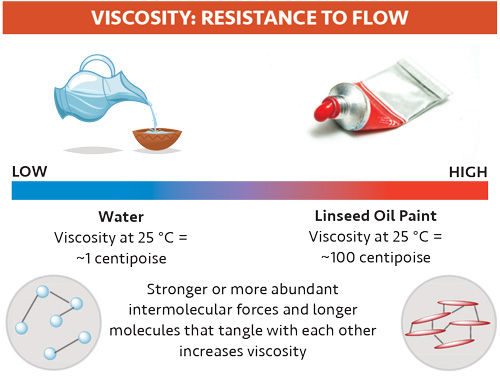

Viscosity is a substance’s resistance to flow, or more specifically, how easily molecules move past each other. Small molecules, such as water, tend to move past each other easily and have low viscosity. Longer, larger molecules, such as oils, get tangled and don’t move past each other easily and thus, have higher viscosity.

In 3D printing, viscosity determines how easily the material can be extruded from the printer nozzle. Materials with high viscosity require more force to extrude, while those with low viscosity may extrude with less force, but their low viscosity may mean they do not hold their shape.

“A big difference you have to watch out for with 3D printing of food versus 3D printing a plastic, for example, is gravity,” says Linette Kucsma, cofounder and chief marketing officer at Natural Machines. When printing plastics, 3D-printer nozzles heat the material to its melting point as it comes out of the tip, and the plastic then hardens quickly as it cools. That process can work for some foods, such as chocolate, but not for others, such as peanut butter or cream cheese.

Ingredients that have the consistency of frosting are easiest to work with. Meats can be pulverized into that state, but vegetables, which have high water content, may need to be combined with a thickening agent, such as xanthan gum, Blutinger says.

He and his colleagues are also exploring ways to print non-paste materials such as powders, solids, liquids, and gels. Pastes can also serve as the structural components that hold together oozier or more solid materials, according to Michael Okamoto, a food material scientist in Oleksyk’s lab.

Making Meat

Satisfying all these requirements is far from trivial, even for a relatively straightforward creation like the tailored nutrient bars that Oleksyk’s team is developing for soldiers. And, if the goal is to make something with a complex structure, creating a printable version is exceedingly more complicated.

For example, Redefine Meat is using 3D printing to create plant-based products that reproduce the structure, texture, and taste of beef steaks. “Meat”—which is muscle—“has a very sophisticated structure meant to provide the animal with the right function, mainly movement,” says Daniel Dikovsky, Redefine Meat’s head of innovation and technology.

The company analyzes meat’s characteristics with a standard compression test and other custom tests to see how it changes and resists being chewed, which depends on the orientations of the muscle fibers. Redefine Meat also re-creates how the muscle fibers align with and adhere to each other, using 3D printers to deposit the company’s proprietary plant-based fibers.

The idea, Dikovsky says, is to truly mimic the different components of a bite of steak, such as the muscle fibers, fat inclusions, and connective tissue, and to simulate the experience of eating it—all the way down to the aroma, flavor, and juices.

Whatever the ingredients, what’s still unknown is how the 3D-printing process might alter a food’s nutritional profile. So far, the effect seems minimal, according to Okamoto. Some nutrients, such as vitamin C, are inherently unstable, so forcing them through the printer’s tubes and syringe might degrade them, especially when heat is involved, he adds.

Researchers’ efforts to combine 3D printing with cooking are adding a twist to nutritional calculations. Lipson’s team added lasers to a food printer and used them to cook ground chicken breast as it emerged from the machine. The researchers are now working with Okamoto to test how laser cooking affects nutrient retention.

“Nobody has done laser cooking before, ever,” Lipson says. He speculates that integrating cooking into the process, whether with lasers or some other form of heat, will be what puts 3D-printed food on the map and transforms this process into a full-fledged form of making a dish, from start to finish.

Meals of Tomorrow

In addition to providing a novel way for home chefs to move beyond their microwaves and food processors, 3D-food printing may have other uses. For example, 3D-food printing may help improve the appetites of people with dysphagia, who have difficulty swallowing, which can be caused by brain disorders, such as multiple sclerosis or Parkinson’s disease.

Dysphagia often requires people to follow a diet of pureed foods, which have been run through a blender, draining an eater’s pleasure in eating. But 3D printing allows foods to be rebuilt in their original shape, but with a texture that will allow it to be eaten by dysphagia sufferers, Oleksyk explains. Eating peas with a fork, even if they’ve been reconstituted, is far more enjoyable than slurping them through a straw, she says.

Researchers are also investigating how 3D printing can be used to stave off hunger and provide nutritional support to people in low-income settings. C. Anandharamakrishnan, director of India’s National Institute of Food Technology Entrepreneurship and Management, is using the approach to develop snacks fortified with protein and fiber that can be provided as supplements in government-run programs focusing on women’s and children’s nutrition.

The snacks could be printed in a rotating array of cartoon shapes and colors and potentially produced cheaply on a local level, Anandharamakrishnan says. His team created 3D-printable chocolate-based bars containing different amounts of protein and fiber that children deemed tasty in tests of acceptability. The institute plans to conduct pilot trials of the snacks in schools to study whether they boost kids’ nutritional profiles.

Beyond these uses, there’s also the sheer gastronomical joy of exploring completely new food experiences. Lipson says, “So far, we’ve only tasted a tiny amount of things that somebody figured out how to make. There’s so much more that’s possible that we’ve never tried—because we didn’t have the tools.”

REFERENCES

Bomgardner, M. 3-D Printing Seeks Commercial Markets. Chemical & Engineering News, March 22, 2017: https://cen.acs.org/articles/95/i13/3-D-printing-seeks-commercial-markets.html [accessed Nov 2023].

Tullo, A.H.. The 3-D Printing Industry Tries to Make Body Parts. Chemical & Engineering News, November 24, 2019: https://cen.acs.org/materials/3-d-printing/3-D-printing-industry-tries/97/i46 [accessed Nov 2023].

Evarts, H. Honey, the 3D Print–I Mean, Dessert–Is Ready! Columbia University School of Engineering, March 21, 2023: https://cen.acs.org/materials/biomaterials/New-3D-printed-muscle-strong/99/i27 [accessed Nov 2023].

Harwitz, E.. New 3D-Printed Muscle Is the Strong, Sensitive Type. Chemical & Engineering News, July 26, 2021: https://cen.acs.org/materials/biomaterials/New-3D-printed-muscle-strong/99/i27 [accessed Nov 2023].

Bomgardner, M.M.. The To-Do List for ‘Clean’ Meat. Chemical & Engineering News, October 21, 2018: https://cen.acs.org/business/food-ingredients/list-cleanmeat/96/i42 [accessed Nov 2023].

This article was adapted from “3D-Printed Foods Enter the Kitchen,” which was originally published in Chemical & Engineering News on February 2, 2022.