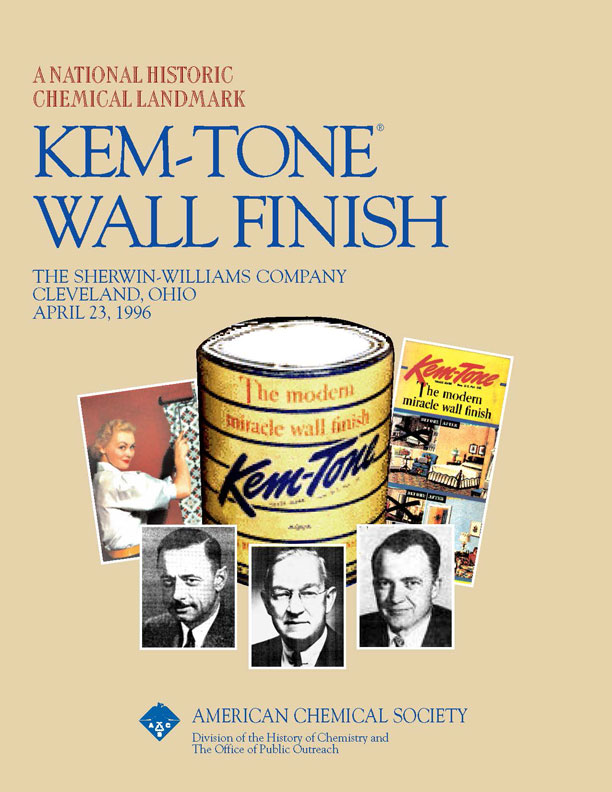

Waterborne Interior Paint: Kem-Tone Wall Finish

Dedicated April 23, 1996, at The Sherwin-Williams Company in Cleveland, Ohio.

In 1941, The Sherwin-Williams Company introduced Kem-Tone© Wall Finish, the first commercially successful, durable, waterborne interior wall paint. The product was based on the commercial innovation of emulsifying casein and linseed oil as binders. This technology led to the development of improved waterborne paints by replacing naturally occurring binders with synthetic ones. The innovative technology that made Kem-Tone© a success permanently changed the architectural painting habits and products of the United States.

Contents

World War II Brings Changes to Paint Industry

During World War II, the paint industry geared up for defense production. Thousands of military items required paints, including camouflage paint for tanks; aircraft, ship, and truck finishes; and coatings for guns and bombs. Every soldier was equipped with many painted items, some of which had their own special finishes. In addition, construction equipment, water supplies, and electrical lighting systems necessary to a military campaign also required paint.

Sherwin-Williams, a leading paint manufacturer based in Cleveland, Ohio, worked to accommodate this defense conversion. Plant engineers converted old equipment to new manufacturing uses. Chemists experimented with old, almost forgotten oils and resins and treated them with modern processing equipment. Purchasing agents combed the country for raw materials so that shortages would not halt production.

Shortages affected every corner of life during the war, from women who gave up stockings because silk was unavailable, to paint manufacturers who were required to ration linseed oil, a common paint binder. These constraints led Sherwin-Williams to accelerate their research into new coatings concepts. Their chemists took casein, a milk protein used by the ancient Egyptians for making paint, and emulsified (or suspended) varnish in it. They then added a number of other ingredients, with water as the largest component, to create a water-based paint.

The result was Kem-Tone© paint, a fast-drying emulsion that met with instant public acceptance and would ultimately become one of the best-selling paints in the United States. Kem-Tone© paint became the first widely accepted waterborne interior wall paint with sufficient binding power to allow washability.

Developed by a team of Sherwin-Williams chemists, Kem-Tone© paint did not depend on organic solvents (based on carbon, such as petroleum derivatives), and it reduced the required amounts of traditional binders, which were in short supply because of the war. Technologically, the chemists at Sherwin-Williams showed that it was chemically and commercially possible for a paint emulsified in water to produce a durable coating.

Kem-Tone© was registered as a trademark on Sept. 23, 1941. In the next three years, more than 10 million gallons would be sold.

The widespread acceptance of Kem-Tone© paint was accelerated by the simultaneous introduction of the hand-roller (called Roller-Koater™), which made application by do-it-yourselfers very easy. Here, too, wartime shortages played a significant role. Richard Adams, an engineer for Sherwin-Williams, invented and patented the roller as an alternative to brushes, which were in short supply because the war between China and Japan restricted the availability of hog bristles.

Kem-Tone© paint and the Roller-Koater™ applicator ushered in a new era in the do-it-yourself paint market, which comprises about 50 percent of the architectural coatings (paints applied to residences) sold today. The innovative chemistry of Kem-Tone© paint also opened the door to continued developments in waterborne paints, which account for approximately 80 percent of all the architectural coatings sold today.

History of Paint

The abundance and widespread use of paint in our daily lives makes it easy to take paint for granted. A look at the chemistry of paint leads to a better appreciation of its complexities.

Paint is a liquid composition that dries to an opaque film. It is composed of four basic types of ingredients: pigments, which are powders that give opacity and color; binders, which act like glue to hold the pigments together and cause the film to adhere to the surface being painted; liquids, which make the paint thin enough to spread on a surface, and additives, which perform special functions such as thickening, reducing mildew, and more.

Paints are generally classified as either solvent-borne or waterborne. Solvent-borne wall paints, such as oil paints, use a petroleum derivative (for example, mineral spirits) as the solvent. Waterborne paints use water.

Waterborne wall coatings prevailed from prehistoric cave paintings up to medieval wall paintings. Natural proteins were used as binders for the pigments. Tempera used egg whites as a binder; distemper, a similar waterborne paint, used animal glues from hides and hoofs. Whitewash used milk casein to bind lime (calcium hydroxide) onto Tom Sawyer's fictional fence. But all these exhibited poor washability and durability.

Linseed-oil-bound pigments — used by the ancient Egyptians, early Romans and Renaissance artists such as da Vinci and Michelangelo — were more durable, but were scarce until the linen industry expanded to provide ample flax seed, from which linseed oil was pressed. Hardening of the soft linseed oil films by rosin and adding volatile turpentine from the naval stores industry enhanced varnishes for Stradivarius violins, fine furniture and wooden floors. Turpentine was the only historic volatile organic solvent to control paint viscosities until the coke and petroleum industries distilled various naphthas.

These separate crafts came together only in the 1930s, when brilliant exterior waterborne paints enhanced and survived the 1933 Century of Progress Exposition in Chicago and the 1939-40 World's Fair in New York City.

Advantages of Kem-Tone© Wall-Finish

Sherwin-Williams chemists used science to combine two chemical opposites — oil and water — to make Kem-Tone© paint. Their chemical innovation was to emulsify, in an aqueous system, traditional solvent-borne binders with casein and other traditional paint ingredients. The binders were casein, linseed oil and, later, tall oil (obtained from wood pulp). This technique set a new standard for the improvement of water-based paints. Eventually, as the product evolved, newly developed synthetic binders replaced the ones used in the original Kem-Tone© paint.

Kem-Tone© paint, which was introduced in 1941 and augmented Sherwin-Williams' family of "Kem" (standing for “chemically evolved material”) products, was the first multi-million-gallon, commercially accepted interior wall paint emulsified in water. The flat, interior finish covered with a single coat, dried in one hour, had greatly reduced paint odor, and could be washed without removing the color. After painting, cleanup was easily accomplished with soap and water. These benefits were summarized in the advertising slogan, "No Muss, No Fuss, No Bother."

A Kem-Tone© demonstration took place at Gimbel Brothers department store, New York City, in 1942. Kem-Tone© paint's ease of application was enhanced by the introduction of the Roller-Koater™ paint roller. Inexperienced painters found that the applicator was faster to use than brushes and provided more even coverage. This made it easier for homeowners to become do-it-yourself painters — an attractive alternative during the labor shortages of World War II.

Kem-Tone© paint had another great advantage: It completely covered wallpaper, plaster, and painted walls, without requiring messy primers, sealers, or thinners. Soon Kem-Tone© and other waterborne paints supplanted wallpaper as the decorative wall finish of choice in the United States.

The introduction of Kem-Tone© paint was the milestone that showed the viability of durable, washable water-based paint and led the way for future improvements. For example, after World War II, the Dow Chemical Company searched for ways to use its styrene-butadiene polymer (40 parts styrene, 60 parts butadiene), which it had developed for the United States Synthetic Rubber Program during the War. The search led Dow to develop styrene-butadiene latex (60 parts styrene, 40 parts butadiene) as a binder in water-borne paints.

Dow's binder helped to create a new Sherwin-Williams product: latex paint. In the late 1940s, the company introduced Super Kem-Tone© paint, which used styrene-butadiene latex as the principal, but not sole, binder. This significantly improved the adhesion and durability of waterborne paints.

Since the 1940s, paints emulsified in water have passed through several additional phases. Styrene-butadiene latex paints yielded to new improvements, such as vinyl acrylic and acrylic latex binders for water-based paints.

The Kem-Tone© Development Team

The key players in the development and introduction of Kem-Tone© paint were Nathan E. Van Stone, James V. Hunn, and Donald A. Kohr, Jr., a team of Sherwin-Williams chemists who shared a commitment to finding a new type of paint. Under the leadership of Van Stone, each member of the team successfully built upon each other's individual research in resins and emulsification.

The research into new coating concepts that led to Kem-Tone© paint began as early as 1930, when Sherwin-Williams established a central research laboratory in Chicago known as Allied Research. In 1933, it established an additional research department called Resin Research. It was there that James Hunn began to investigate innovative binders for paints such as new alkyds (synthetic polymers formed from complex alcohols and acids) and phenolics (synthetic polymers made from aromatic organic compounds containing OH groups). Hunn's chemical innovations included a development of the linseed oil-limed rosin varnish that was eventually used in Kem-Tone© paint. This represented an important transition from simple waterborne protein paints, to oil-in-water modified protein paints.

In 1938, Van Stone was promoted from Sherwin-Williams' operations in Chicago to Vice-President and Director of Paint Manufacturing in Cleveland. This move was the beginning of the specific research and development that led to Kem-Tone© paint, for Van Stone had the foresight to realize that Hunn's resin research and further emulsification research could lead to significant breakthroughs in water-based coatings.

Van Stone brought with him 20 years of experience in the Dry Color and Chemical Products Departments, where pigments prepared in a water system were "flushed" (mixed with emulsifiers and oil-type binders), creating non-water, liquid, color concentrates. These were formulated into both solvent-borne coatings and into the textile industry's waterborne printing colors used for patterns on cotton fabric. This technology extended logically into both Kem-Tone© paint and the camouflage paints that were used in large volume in the latter years of World War II.

It was this vision and understanding of chemical research that led Van Stone to appoint Donald Kohr as section supervisor of emulsion and waterborne paint research for the company. Van Stone served as the crucial link between Hunn's resin and polymer research and Kohr's application of this research to produce emulsion paints.

While directing waterborne paint research, Kohr employed Hunn's formulations of linseed oil/rosin varnish. Kohr also applied Hunn's work with refined polymerized tall oil to reinforce casein and corn protein as binders. The result was the introduction of Kem-Tone© paint and eventually the evolution of more durable waterborne paints.

Landmark Designation and Acknowledgments

Landmark Designation

The American Chemical Society designated the first modern water-based paint, Kem-Tone© Wall-Finish, as a National Historic Chemical Landmark in a ceremony at The Sherwin-Williams Company in Cleveland, Ohio, on April 23, 1996. The plaque commemorating the event reads:

In 1941, The Sherwin-Williams Company introduced Kem-Tone©, the first commercially successful multi-million-gallon, waterborne interior wall paint with colors that could withstand rubbing or washing. The product was based on the chemical innovation of emulsifying casein, linseed oil and, later, tall oil as binders. This technology led to the development of improved waterborne paints by replacing naturally occurring binders with synthetic ones. The new product, along with the Sherwin-Williams Roller-KoaterTM applicator, spurred the World War II development and expansion of ‘do-it-yourself’ painting. The innovative technology that made Kem-Tone® paint a success permanently changed the architectural painting habits and products of the United States.

Acknowledgments

Adapted for the internet from “Kem-Tone© Wall Finish,” produced by the National Historic Chemical Landmarks program of the American Chemical Society and The Sherwin-Williams Company in 1996.

Learn more: About the Landmarks Program

Take action: Nominate a Landmark and Contact the NHCL Coordinator

Acrylic Emulsion Technology

Developed by Rohm and Haas in the 1940s and dedicated as a National Historic Chemical Landmark in 2008, water-based acrylic emulsion technology was another development in the post-WWII paint industry and was a leap forward in acrylic chemistry. Learn more.