By: Juan Colberg, Jared Piper, and Paul Richardson

Pfizer Green Chemistry Program, the early days

One definition for Green Chemistry is the design of chemical products and processes that reduce or eliminate the use or generation of hazardous substances, and waste and reduce impact on our natural resources. We at Pfizer have embraced this concept and applied it across the life cycle of our products, including their design, manufacture and use.

Pfizer’s Green Chemistry began in 2001 as a grassroots effort by a small group of colleagues who wanted to reduce the amount of waste the company disposed of from their chemical operations. Under the Green Chemistry banner, and notably with the support of senior leadership, Pfizer, a year later, formally established the program that continues to this day, which now has expanded to all our chemical operations within R&D and commercial groups.

As part of these efforts, the green chemistry team has developed tools based on solvent selection, reagent guides and LCA/PMI (life cycle analysis/process mass intensity) metrics analyses amongst others, that have established a foundation in educating colleagues on making greener chemistry decisions in delivering our portfolio to patients.

Early Development

Speed and the potential high risk of compound attrition are often affiliated with medicinal chemistry programs in the discovery phase and are often cited as to why “Green Chemistry” and long-term “Sustainability Implications” are often not amongst a scientist’s primary considerations when making project-based decisions.

However, the Pfizer Green Chemistry program encourages scientists to take a more holistic view of the drug-discovery process and consider how early decisions can provide long-term beneficial impacts both for the program as well as from a sustainability perspective. In addition, the over-arching philosophy within the program, promoting “voluntary restraint over enforced constraint”, aligned with interactive training enabled by a suite of the previously mentioned industry-leading green chemistry tools, provide an environment in which judicious decision-making leads to “win-win” outcomes throughout the portfolio.

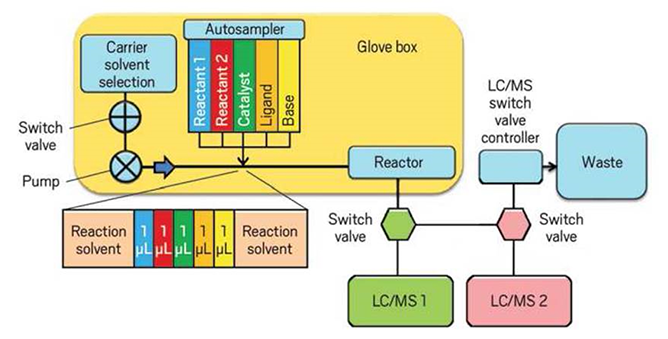

To illustrate this, whereas developing greener synthetic routes to a specific compound within discovery can lead to its accelerated progress through development, such approaches can also lead to the expedited synthesis of compound analogues, thus shortening the “design-make-test” cycle, leading to more efficient identification of a lead molecule. Similarly, in the drug design space, optimization of physicochemical properties, such as lipophilicity, not only are key factors in influencing the success of a compound as a drug, but also have a profound downstream effect on the propensity for a molecule or its metabolites to persist in the environment. A further important consideration is the growing impact of emerging technologies within synthetic organic chemistry, such as biocatalysis, flow chemistry, high-throughput experimentation (Figure. 1) and photoredox- and electrochemically-mediated transformations.

With respect to these, it is important to appreciate the cross-line applicability of such technologies (although variations obviously exist in their application and practice), and given this, the translation of the advantages that these provide from discovery through to API manufacture represents a critical endeavor driven by seamless communication across lines. The growth in interest in AI/ML (artificial intelligence/machine-learning) within drug discovery and development provides a further avenue to exploit, and within the medicinal chemistry space, presents the opportunity to not only enable the efficient exploration of novel chemistry space through developing innovative syntheses, but also minimize the number of “real” synthetic molecules that one has to profile to identify new bioactive moieties. Aligned with substrate-sparing nanomole-based technologies in compound synthesis, these practices will lead to opportunities for streamlined drug discovery cycles that minimize waste.

Figure 1. Pfizer Automated Flow System- Array of valves, pumps, autosampler and LC/MS systems to rapidly screen reactions, under a range of condition and solvents, for early identification of greener processes.

Process Chemistry and Commercialization Chemical Routes

Throughout the development of a commercial route for an active pharmaceutical ingredient (API), process chemists face numerous challenges, including the need to select the best route, starting materials, synthetic methods, and technologies that provide the desired target, under a timeline dictated by project needs and loss of exclusivity due to patent lifetimes. Green chemistry is a key focal point in accomplishing these requirements. The overall goal of a process chemist is to develop the most cost-effective process for large scale synthesis of an API.

A cost- effective process typically has high overall yield, little waste (thus minimizing expenditure on waste disposal as well as raw materials) and good reagent/reactant (with a strong emphasis on catalysis) utilization factors, among others. As development progresses and these factors improve, the process becomes greener. Metrics, such as PMI and Route Mass Efficiency (RME), improve as the yield increases and the reagents are used more sparingly. The Environmental Factor (E-factor) will also decrease over time as the waste is decreased with more efficient work-ups, telescoping and reduced use of solvent.

Green chemistry tools and metrics guide the process chemist in the selection of preferred solvents or reagents used in a chemical synthesis, and are paramount in obtaining successful reaction outcomes while addressing sustainability. Many reactions described in the chemical literature contain transformations carried out using solvents and reagents selected to maximize yield or selectivity, but authors rarely discuss if the selections pose either an environmental/safety concern and/or are strictly controlled by legislative or regulatory agencies.

For industrial chemists, there is a greater focus on the choice of solvents and reagents, since products are prepared on a much larger scale, and therefore have the capability of generating significant amounts of waste. In addition, many pharmaceutical, fine chemical, and chemical manufacturing industries are committing to substantial green chemistry initiatives aligned with societal expectations.

The practicing process chemist of today continues to have at their disposal many tools for implementing green chemistry from the outset, including a growing database of scientific publications and successful examples on the topic to aid in the design of more environmentally responsible processes. Aligned with the 12 Principles of Green Chemistry, process chemists continue to forge partnerships with academic institutions to design, develop, and implement innovative technology solutions to advance green chemistry. Areas such as biocatalysis, continuous manufacturing, non-precious metal catalysis, in silico computer methods/molecular property predictions, and process analytical technologies (PAT) are leading to creative solutions that will lead to greener outcomes for commercial launch.

Moving forward

In the absence of government action, expectations continue to rise on the Pharmaceutical industry to demonstrate leadership regarding climate change. Recognizing the profound societal and public health impacts that may result from such environmental issues, Pfizer’s corporate commitments and stated purpose to establish ‘breakthroughs that change patients’ lives’, guides our actions to mitigate against factors that impact climate change, manage the use of natural resources, and reduce waste arising from manufacturing of medicines and vaccines, in both our internal and external operations.

As part of this commitment, in March 2020, Pfizer announced the creation of a $1.25 billion Sustainability Bond for Social and Environmental Impact. Proceeds of these bonds will be used to improve access to essential services, green buildings, and investments intended to further improve the environmental performance of Pfizer facilities, while reducing the impact of our operations of energy usage, water and waste management, and pollution reduction. With respect to green chemistry, this will include minimizing the environmental impact across the supply chain and life cycle of our products, through developing greener processes across our portfolio as defined through analyses of benchmarking metrics.

This article has been edited for length and clarity. The opinions expressed in this article are the author's own and do not necessarily reflect the view of their employer or the American Chemical Society.

Copyright 2022 American Chemical Society (All Rights Reserved)