Wallace Carothers and the Development of Nylon

Dedicated October 26, 1995, at the DuPont nylon plant in Seaford, Delaware (now operated by Invista), and November 17, 2000, at the DuPont Experimental Station in Wilmington, Delaware.

Commemorative Booklet—The First Nylon Plant (PDF)

Commemorative Booklet—The Establishment of Modern Polymer Science By Wallace H. Carothers (PDF)

The establishment of modern polymer science by Wallace Carothers and the first nylon plant, built by DuPont, at Seaford, are two deeply interwoven National Historic Chemical Landmarks. The research of Carothers not only confirmed the existence of molecules of extremely high molecular weight, but led as well to the development of nylon, the first totally synthetic fiber used in consumer products.

Contents

- Modern Polymer Science

- Wallace Carothers Begins Polymer Research at DuPont

- Research on Synthetic Rubber and the Discovery of Neoprene

- Development of “Superpolymers”

- Nylon: Discovery, Development and Production at DuPont

- Challenges in the Production of Nylon Fibers

- Wallace Carothers’ Legacy: An Extraordinary but Brief Career

- Further Reading

- Landmark Designation and Acknowledgments

- Cite this Page

Developments in Modern Polymer Science

When Wallace H. Carothers joined the research staff of E.I. du Pont de Nemours and Company (DuPont) in early 1928, polymer science was still in its infancy — poorly understood and full of uncertainties.

By the early 20th century, chemists had learned that many materials were polymeric — including such natural substances as proteins, cellulose, and rubber. Other polymers had been synthesized in the laboratory from smaller molecules like styrene, vinyl chloride, and acrylic acid. At least one synthetic polymer, Bakelite®, a hard resin produced from phenol and formaldehyde by Leo H. Baekeland in 1907, was a big commercial success. Chemists knew, too, that polymers were molecules of high molecular weight (for example 40,000 or more) made up of huge numbers of smaller chemical units. But how these units were arranged and held together was not clear. Many eminent chemists believed that polymers were aggregates, perhaps colloids, consisting of relatively small molecules held together by some intermolecular force of uncertain nature.

In the early 1920s, the German organic chemist (and 1953 Nobel laureate) Hermann Staudinger postulated that polymers consisted of units linked together by the same covalent bonds found in smaller organic molecules. Throughout the 1920s, Staudinger supported his view with new experimental evidence, and other chemists, among them Karl Freudenberg, Michael Polanyi, Kurt Meyer, and Herman Mark, came up with additional evidence backing Staudinger. The subject, nevertheless, remained controversial well into the 1930s.

Carothers had no direct contact with these chemists, but his ideas were generally in line with those of Staudinger. His research approach, on the other hand, was quite different. Whereas Staudinger focused his study on the analysis of natural polymers, Carothers built up polymers by reacting small organic molecules by means of well-known reactions — for example, by combining dicarboxylic acids with diols or diamines — to form long, macromolecular chains.

In addition to the many experimental studies, Carothers believed that mathematics could be applied to understand the formation and properties of polymers. To this end, Paul J. Flory was hired in 1934 and introduced to polymers by Carothers. The seminal ideas they advanced provided the foundation of many of the theoretical methods for studying polymers used to this day. Flory's accomplishments were recognized with the 1974 Nobel Prize in chemistry.

The research accomplishments of Staudinger and Carothers, along with that of their colleagues, during the 1920s and 1930s laid the foundations of modern polymer science and today's plastics, synthetic fiber, and rubber industries.

Polymer Landmarks

The links below will direct you to more National Historic Chemical Landmarks about developments in polymer chemistry and production:

Bakelite®: The World’s First Synthetic Plastic

Foundations of Polymer Science: Herman Mark and the Polymer Research Institute

Foundations of Polymer Science: Hermann Staudinger and Macromolecules

Wallace Carothers Begins Polymer Research at DuPont

In late 1926, Charles M. A. Stine, director of DuPont’s chemical department in Wilmington, Delaware, convinced the company's executive committee to establish a continuing program in fundamental research. Only a handful of industrial firms had such farsighted programs. For most firms, research simply meant problem solving and process improvement. But Stine proposed what he called "a radical departure from previous policy" — a program of "pure science" with "the object of establishing or discovering new scientific facts" without obvious practical applications. Stine argued that DuPont's support of work in pure science would enhance the company's prestige, make recruiting Ph.D. scientists easier, and cement bonds to academic chemistry departments. Finally, he added, something of practical value might come out of it.

Stine chose five lines of study — colloid chemistry, catalysis, the generation of chemical and physical data, organic synthesis, and polymerization — and set out to recruit the very best chemists to head each field. In 1927, he persuaded Wallace H. Carothers, a brilliant young instructor in organic chemistry at Harvard University, to head the program in organic synthesis.

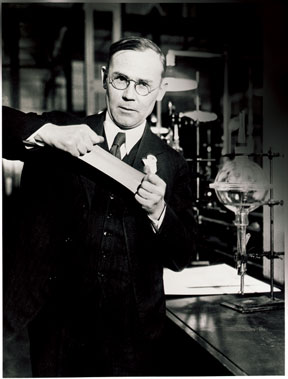

Wallace Carothers was born in Burlington, Iowa, on April 27, 1896, the son of Presbyterians of modest means. His father taught at the Capital City Commercial College in Des Moines, Iowa, and young Carothers spent a year there. In 1915 he enrolled at Tarkio College, a small Presbyterian-supported school in northwestern Missouri. There he majored in chemistry while helping in the school's floundering commercial department. When the chemist who ran the college's one-man science department departed in 1918, Carothers, then a senior, took over the college's chemistry classes.

After graduating from Tarkio in 1920, Carothers continued his studies at the University of Illinois, at the time the preeminent school in the United States for training organic chemists. There, he earned a Master's degree in 1921 and a Ph.D. under Roger Adams in 1924. Years later, Adams characterized Carothers as "the best organic chemist in the country."

While an instructor at Illinois, Carothers became interested in the electronic theory of valence to explain how atoms in organic molecules bond together. It was a theory propounded by the physical chemist G. N. Lewis of the University of California at Berkeley. But most organic chemists of the time ignored that theory, if they did not dismiss it outright. Carothers published a paper on the electronic nature of the carbon-carbon double bond in the Journal of the American Chemical Society in 1924. It marked his growing interest in theoretical as well as experimental organic chemistry.

In 1926, Carothers accepted a teaching post in organic chemistry at Harvard University, but he was uncomfortable as a classroom lecturer. When DuPont offered Carothers the opportunity to do fundamental research, at first he was reluctant to accept. He agreed to do so once convinced that he would be free to work on whatever interested him and that he would command an ample budget for supplies and equipment. Stine also provided Carothers with a staff of newly minted Ph.D.s from Colorado, Johns Hopkins, Illinois, MIT, and Michigan. Besides, his $6,000 a year salary would nearly double what Harvard was paying him.

Shortly after arriving at the newly constructed laboratory (later dubbed "Purity Hall") on February 6, 1928, Carothers began to study the structure and synthesis of polymers. He concluded from the literature that long molecules could be strung together from small organic compounds that had a reactive (functional) group at each end. He called these resulting products "condensation polymers" because another compound (such as water) would be split off as a byproduct. Carothers and a small group of young Ph.D. chemists began by reacting dibasic acids (containing two carboxylic acid, -COOH groups) with diols (two alcohol, -OH groups). This reaction, known as esterfication, was roughly akin to linking together a chain of paper clips. The resulting long chain molecules were polyesters.

Progress was rapid, and the resulting polymers theoretically interesting. But their molecular weights were 4,000 or less. Carothers was aiming for larger molecules. He concluded that the water formed during the esterfication reaction was limiting the chain length.

Research on Synthetic Rubber and the Discovery of Neoprene

Meanwhile, in 1930 Carothers had been asked by Elmer Bolton, the new head of DuPont's chemical department, to look into polymers based on acetylene. Unlike Stine, who emphasized pure science, Bolton believed that research should be aimed at clearly defined applications. The freewheeling days of fundamental research at DuPont were fading.

Bolton, who previously had headed DuPont's research on dyes, had long been interested in producing a synthetic rubber. In the late 1920s he had followed the research of Father Julius Nieuwland of Notre Dame University, who used a cuprous chloride catalyst to combine two or three acetylenes into mono- or divinylactetylene. Bolton realized that these compounds were similar to isoprene, the molecule that is the basic structural unit of natural rubber.

Carothers assigned Arnold Collins to make a very pure sample of divinylacetylene. While distilling the products of the acetylene reaction in March 1930, Collins obtained a small amount of an unknown liquid, which he put aside in stoppered test tubes. A few days later he found that the liquid had congealed into a clear homogenous mass. When Collins dislodged the mass from its container, it bounced. Analysis showed that the mass was a polymer of chloroprene, formed with chlorine from the cuprous chloride catalyst. Accidentally, Collins had prepared a new synthetic rubber.

DuPont began large-scale production of polychloroprene, marketed under the name Duprene (later changed to neoprene), in 1932. Neoprene was difficult and expensive to manufacture, however, and it didn't really rival natural rubber, which was selling for only a few cents per pound in the early 1930s. Neoprene — which was resistant to weather, oil, chemicals, and heat — found several relatively small but profitable uses.

Development of “Superpolymers”

After Stine hired him, Carothers decided to concentrate on polymers, those giant molecules that are the building blocks of such familiar substances as rubber and cotton. At that time, most scientists believed polymers were aggregates of small molecules bound by unknown or undefined forces, and not by ordinary chemical bonds. Carothers believed that polymers were molecules hooked together end-to-end in long chains by ordinary bonds. To test his theory, he proposed to create polymers by using well-known chemical reactions to join together many small molecules. A few days after starting work, he wrote that he intended:

to study the reactions of substances xAx on yBy where A and B are divalent radicals and x and y are functional groups capable of reacting with each other. Where A and B are quite short, such reactions lead to simple rings of which many have been synthesized by this method. Where they are long, formation of small rings is not possible. Hence reaction must lead either to large rings or long chains.

Using dibasic acids and glycols, he was successful in producing polyesters with molecular weights of 2,300 to 5,000. He then introduced the molecular still, a laboratory tool that made it possible to produce polyesters with molecular weights as high as 25,000.

Carothers called these materials "superpolymers." They were tough, opaque solids which became transparent, viscous liquids when heated. Two important observations were made by his chief associate, Dr. Julian Hill: first, that filaments could be obtained by pulling threads like taffy from the molten polymer; second, that these filaments when cooled could be drawn many times their original length, enhancing their properties Whether dry or wet, they became strong and elastic — the characteristics of a promising textile fiber. Filaments could also be produced by dissolving the polymer in chloroform and passing the viscous solution through a standard rayon spinneret.

In 1931 the company applied for a patent on linear condensation polymers, and Carothers and Hill presented a paper to the American Chemical Society in which they disclosed superpolyesters that could be extruded and drawn into a fiber with properties superior to silk.

Carothers' group experimented with many compositions, but none was a suitable candidate for a textile fiber. Their melting points were too low, and they were too sensitive to solvents. Though his research continued, by 1933 work on fully synthetic fibers had come to a halt.

U.S. Synthetic Rubber Program

When the natural rubber supply from Southeast Asia was cut off at the beginning of World War II, the United States and its allies faced the loss of a strategic material. A consortium of companies involved in rubber research and production united in a unique spirit of technical cooperation and dedication to produce a general purpose synthetic rubber on a commercial scale to meet the needs of the U.S. and its allies during World War II.

Learn more about the U.S. Synthetic Rubber Program.

Nylon: Discovery, Development and Production at DuPont

1930 was a banner year for Carothers' research group. While Collins, through his careful observation, was uncovering the polymer that would become neoprene, Carothers and his closest research associate, Julian Hill, had found that the unwanted water formed during esterfication could be removed by running the reaction in a molecular still, a recently invented device. In late April 1930, Hill synthesized a polyester in the still, touched the hot mass with a glass rod, and stretched "this festoon of fiber." He had formed a polyester with a much higher molecular weight than before, about 12,000. Moreover, the cooled fibers became strong and elastic when pulled out farther. This "cold drawing" process orients the previously helter-skelter polymer molecules along a single axis. The first synthetic fibers had been created.

Hill then produced a wide array of polyester fibers, which, although they were scientific marvels, were of no practical value. All of the fibers melted in boiling water, and they dissolved in many organic liquids. Carothers and Hill turned to polymerizing dibasic acids with diamines — compounds that had amino (-NH2) groups at either end. Although the products had very high melting points and were relatively insoluble, they proved no more useful as fibers than the polyesters. For a while, Carothers stopped working on such polymers, but Bolton was convinced that a viable fiber was possible.

In early 1934 the polyamide fiber project got back in gear. A wide variety of dibasic acid and diamine polymers were prepared. One of these, synthesized from adipic acid and hexamethylenediamine on February 28, 1935, was called fiber 66 because each of its components had six carbon atoms. It formed fibers that, after cold drawing, were strong, elastic, unaffected by water or most solvents, and had a high melting point. DuPont chose this fiber in July 1935 for full-scale production.

Much development work remained. Although adipic acid was being made in Germany, hexamethylenediamine was only a laboratory curiosity. DuPont engineers had to devise ways to make both chemicals, find a means of extruding the molten polymer through tiny holes (spinnerets) into fine filaments, and design and construct a new production plant. By the time DuPont started building its first plant in Seaford, Delaware, in 1938, more than 230 chemists and engineers had worked on the project at one time or another at a cost of $27 million.

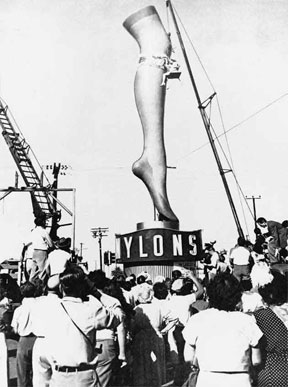

The market development process set off rumors in the textile industry about the new fiber. DuPont kept quiet until the nylon patent was issued in September 1938. The Seaford plant was authorized on October 12, and two weeks later, Stine announced nylon in a nationwide broadcastat the Herald Tribune forum in New York City, on October 27, 1938. Because of the product's silk-like qualities, DuPont planned to target it toward women's hosiery (actually, small amounts also were used as bristles in Dr. West's toothbrushes by 1938). Sample stockings were sold to company office employees in Wilmington in March 1939, and a limited quantity was sold to the public in Wilmington later that year. Demand was overwhelming. They sold out in three hours.

On December 15, 1939, production started on the plant — the first ever designed for an operation never before undertaken. It would cost DuPont $8 million, one-sixth of its 1938 net earnings.

Nylon was a best seller from the outset. The first day nylon stockings were introduced nationwide, May 15, 1940, nearly 800,000 pairs were sold. Seven months later, the company put 4,000,000 pairs on sale nationally. These sold out in four days. The name "nylon," intended to be a generic designation of a class of polymers, became another word for stockings.

By 1941, nylon had captured over 30% of the hosiery market. When the United States entered World War II in December 1941, however, all nylon output was diverted to military needs.

Challenges in the Production of Nylon Fibers

The technical tasks were many. Consider these examples:

Intermediate chemicals. New manufacturing processes for both adipic acid and hexamethylene diamine were developed at the Belle, West Virginia, plant, and new equipment was designed to keep the ingredients hot during transport over the Appalachians to Delaware.

Melt spinning. Before nylon, spinning — the extrusion of polymer to form filaments (as a spider "spins" its web or a silkworm a cocoon) — was done with a solvent. Nylon could be solution-spun, but it also could be spun by melting the polymer. While this offered advantages, it had never been done. "I had nightmares over melt spinning," said Greenewalt. "The problem was the melting point of nylon was very close to the decomposition point. We'd get bubbles, because the decomposition products were gases." The solution, simple in hindsight, was to keep the polymer under high pressure — 4,000 pounds per square inch. Special pumps were designed to operate at these pressures, with small clearances and with no lubricant other than the polymer itself. A new grade of stainless steel had to be used that was abrasion resistant.

The high temperatures, 550º F (285º C), posed other problems. Many types of spinning-cell melting grids were designed to find a candidate that would maintain heated surfaces in spite of the poor thermal conductivity of the polymer. To protect the hot polymer from oxidation, DuPont used a purified grade of nitrogen, which came to be known as "Seaford-grade nitrogen." In addition, the spinning assembly involved radically new engineering developments to produce fibers of the required uniformity. Before the plant was opened, eight different spinning assemblies were constructed, each one embodying the newest ideas.

High-speed spinning and cold drawing. Special equipment was designed for this crucial step. Generators were made to run the windup of the yarn at a speed of 2,000 feet per minute with virtually no variation. The draw rolls — between which the yarn was stretched a uniform amount — had to be manufactured to a tolerance of 1/100,000th of an inch.

Sizing. The size, or surface coating, itself proved a major problem. The first choice corroded knitting needles and gummed up the machines. Candidate after candidate was tried and failed. The clock was ticking. DuPont eventually assigned 30 scientists to work on the problem, and they didn't come up with the answer until the structural steel was up at Seaford and much of the other equipment was installed.

Wallace Carothers’ Legacy: An Extraordinary but Brief Career

While at DuPont, Carothers enjoyed varied interests beyond his research, including art, music, poetry, politics, and sports, and he made many friends in Wilmington. In 1936, he married Helen Sweetman, a chemist in the patent department at DuPont. The same year he became the first industrial organic chemist elected to the National Academy of Sciences. Toward the end of his career, Carothers was subject to increasing periods of depression and, in April 1937, he took his own life.

Carothers confirmed the basic structure of polymers, demonstrating that they were ordinary molecules, only longer. His synthesis of polymers led to the development of nylon, the world's first fully synthetic fiber, and neoprene, a highly resistant synthetic rubber. His early work with polyesters supported the establishment of the polyester fibers industry. These materials remain important articles of commerce to this day. Despite Carothers' relatively brief career, it was an extraordinarily productive one, both in terms of fundamental advances in chemistry and nearly unparalleled commercial success.

Further Reading

- DuPont History (E. I. du Pont de Nemours and Company)

- Wallace Hume Carothers (Chemical Heritage Foundation)

Landmark Designation and Acknowledgments

Landmark Designation

The American Chemical Society designated Wallace Carothers’ contributions to modern polymer science and the development of nylon as National Historic Chemical Landmarks in ceremonies on October 26, 1995, at the DuPont nylon plant (now operated by Invista) in Seaford, Delaware, and on November 17, 2000, at the DuPont Experimental Station in Wilmington, Delaware.

The text of the plaque commemorating the DuPont nylon plant (now operated by Invista) in Seaford, Delaware, reads:

At this site on December 15, 1939, DuPont began commercial production of nylon. Among the earliest successes of a fundamental research program novel in the American chemical industry, nylon was the first totally synthetic fiber to be fashioned into consumer products. Prepared wholly with materials readily derived from coal, air, and water, nylon has properties superior to its natural counterparts, such as silk. Nylon revolutionized the textile industry and led the way for a variety of synthetic materials that have had enormous social and economic impact on the fabric of everyday life worldwide.

The text of the plaque commemorating Wallace Carothers’ contributions to modern polymer science at the DuPont Experimental Station in Wilmington, Delaware, reads:

At this site in 1928, Wallace H. Carothers (1896-1937) began his pioneering studies into the chemistry of giant molecules. He soon confirmed that high molecular weight molecules consist of repeating units of simple molecules (monomers) linked together by chemical bonds to form long chains (polymers), as first proposed in 1920 by German chemist Hermann Staudinger. Carothers excelled at creating polymers, and his work quickly led to the E.I. du Pont de Nemours and Company's highly successful commercial production of neoprene, the first synthetic rubber made in the United States (1932), and nylon, the world's first totally synthetic textile fiber (1939).

Acknowledgments

Adapted for the internet from “The First Nylon Plant,” produced in 1995, and “The Establishment of Modern Polymer Science By Wallace H. Carothers,” produced in 2000, by the National Historic Chemical Landmarks program of the American Chemical Society.

Back to National Historic Chemical Landmarks Main Page.

Learn more: About the Landmarks Program.

Take action: Nominate a Landmark and Contact the NHCL Coordinator.