FOR IMMEDIATE RELEASE

“Metasurface- and PCSEL-Based Structured Light for Monocular Depth Perception and Facial Recognition”

Nano Letters

Many people are familiar with facial recognition systems that unlock smartphones and game systems or allow access to our bank accounts online. But the current technology can require boxy projectors and lenses. Now, researchers report in ACS’ Nano Letters a sleeker 3D surface imaging system with flatter, simplified optics. In proof-of-concept demonstrations, the new system recognized the face of Michelangelo’s David just as well as an existing smartphone system.

3D surface imaging is a common tool used in smartphone facial recognition, as well as in computer vision and autonomous driving. These systems typically consist of a dot projector that contains multiple components: a laser, lenses, a light guide and a diffractive optical element (DOE). The DOE is a special kind of lens that breaks the laser beam into an array of about 32,000 infrared dots. So, when a person looks at a locked screen, the facial recognition system projects an array of dots onto most of their face, and the device’s camera reads the pattern created to confirm the identity. However, dot projector systems are relatively large for small devices such as smartphones. So, Yu-Heng Hong, Hao-Chung Kuo, Yao-Wei Huang and colleagues set out to develop a more compact facial recognition system that would be nearly flat and require less energy to operate.

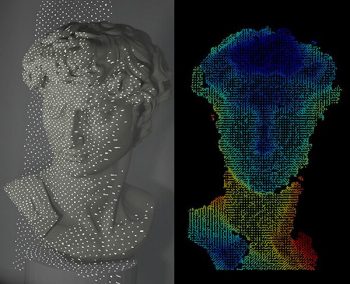

To do this, the researchers replaced a traditional dot projector with a low-power laser and a flat gallium arsenide surface, significantly reducing the imaging device’s size and power consumption. They etched the top of this thin metallic surface with a nanopillar pattern, which creates a metasurface that scatters light as it passes through the material. In this prototype, the low-powered laser light scatters into 45,700 infrared dots that are projected onto an object or face positioned in front of the light source. Like the dot projector system, the new system incorporates a camera to read the patterns that the infrared dots created.

In tests of the prototype, the system accurately identified a 3D replica of Michelangelo’s David by comparing the infrared dot patterns to online photos of the famous statue. Notably, it accomplished this using five to 10 times less power and on a platform with a surface area about 230 times smaller than a common dot-projector system. The researchers say their prototype demonstrates the usefulness of metasurfaces for effective small-scale low-power imaging solutions for facial recognition, robotics and extended reality.

The authors acknowledge funding from Hon Hai Precision Industry, the National Science and Technology Council in Taiwan, and the Ministry of Education in Taiwan.

###

The American Chemical Society (ACS) is a nonprofit organization chartered by the U.S. Congress. ACS’ mission is to advance the broader chemistry enterprise and its practitioners for the benefit of Earth and all its people. The Society is a global leader in promoting excellence in science education and providing access to chemistry-related information and research through its multiple research solutions, peer-reviewed journals, scientific conferences, eBooks and weekly news periodical Chemical & Engineering News. ACS journals are among the most cited, most trusted and most read within the scientific literature; however, ACS itself does not conduct chemical research. As a leader in scientific information solutions, its CAS division partners with global innovators to accelerate breakthroughs by curating, connecting and analyzing the world’s scientific knowledge. ACS’ main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive press releases from the American Chemical Society, contact newsroom@acs.org.

Note: ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies.