Nanotechnology Safety Resources

Resources for Working Safely with Nanomaterials in Laboratories

Nanotechnology underpins many emerging industries and technological innovations, such as artificial intelligence, quantum information science, and advanced manufacturing. Nanotechnology is a collection of sciences that encompasses chemistry, biology, physics, engineering, and advanced computing technology to create or manipulate materials or processes at the nanoscale. The nanoscale is the range from 1 to 100 nanometers. A nanometer is one-billionth of a meter. For reference, a sheet of paper is about 100,000 nanometers thick. Nanoscale matter can behave differently from the same material in a larger bulk form. For example, a material’s melting point, color, strength, chemical reactivity, and more may change at the nanoscale.1

The small size and the corresponding large ratio of surface area to mass lead to a predicted greater biological activity per given mass for nanomaterials, relative to their bulk counterparts.2 Therefore, the properties and behavior of nanoscale forms of a compound cannot simply be extrapolated from those of their larger bulk forms.3 The nanostructure-dependent physical and chemical properties of many engineered nanoparticles may place them in the category of potential hazards. The direct risk that nanoparticles present to human health and to the environment will depend on the physicochemical characteristics of the surface and core of nanoparticles, on the probability of exposure occurring during each stage of their life cycle, and on the extent to which particulate materials exhibit interactions with biological systems associated with their nanostructure.

How Exposures to Engineered Nanomaterials May Occur, and Potential Effects

As the production and use of engineered nanomaterials has grown, so has the workforce handling them.3 Primary routes of exposure for workers and laboratory personnel involved in handling engineered nanomaterials include inhalation, dermal contact, and ingestion.4,5 There is historical awareness that the inhalation of ultrafine particles causes respiratory and cardiovascular effects. In the occupational and laboratory setting, inhalation is a primary focus for exposure assessment and control.6 The potential for adverse health outcomes from inhalation of nanoscale materials depends on many factors, and no single descriptor exists for all nanomaterials.7 Extensive research and field and laboratory evaluations have generated a significant body of knowledge on the safe handling of nanomaterials.

Working Safely with Nanomaterials in the Laboratory (YouTube video)

ACS Guidelines for Safe Handling of Nanomaterials in the Laboratory

The foundation of safe handling of engineered nanomaterials rests on the principles of good laboratory practices.8 The following key considerations are adapted from guidelines provided by Dr. Peter Lichty (Lawrence Berkeley National Laboratory) and comments received from members of the ACS safety community. They follow laboratory safety’s organizing principle of RAMP: Recognize hazards, Assess risk, Minimize risk and Prepare for emergencies.

Recognize Hazards and Assess Risks:

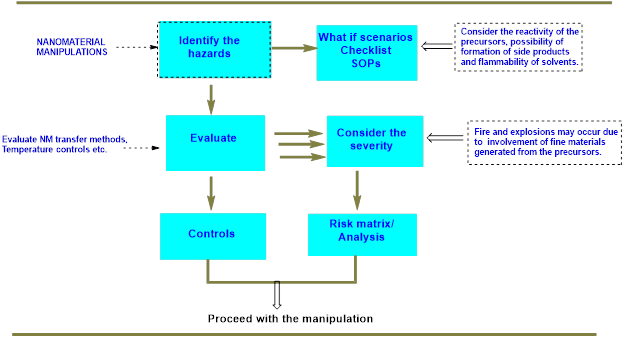

- Be sure to consider the hazards of precursor materials in evaluating process hazards such as acidity, basicity, oxidizing or reducing strength, and flammability. Perform thorough hazard assessment and risk assessment for the nanomaterial syntheses (Figure 1).

- Consideration should also be given to the high reactivity of some ultrafine powdery materials, which poses potential fire and explosion hazards.

- Evaluate nanomaterial transfer methods, temperature controls and other process controls.

Minimize Risks

Selection of Nanomaterials, and Substitution

- Whenever possible, substitute dry nanomaterials with those in solution or bound to substrates.

Engineering Controls

- Given the differing synthetic methods and experimental goals, aerosol emissions controls should be carefully designed for the process, tested, and properly operated to be effective; see the National Institute for Occupational Safety and Health (NIOSH) Protecting Workers During the Handling of Nanomaterials. Controls should meet the respiratory protection standards in the Occupational Safety and Health Administration (OSHA) Personal Protective Equipment, Standard 1910.134 29 CFR 1910.134, if respiratory protection is used.

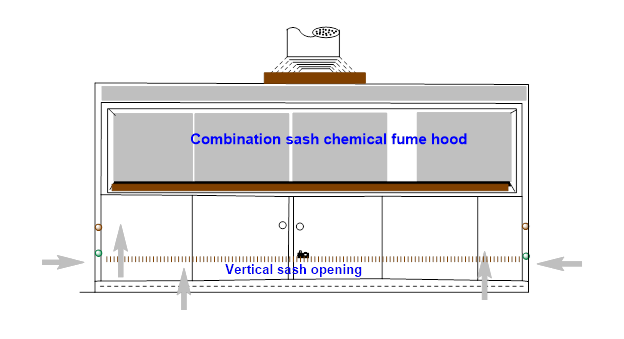

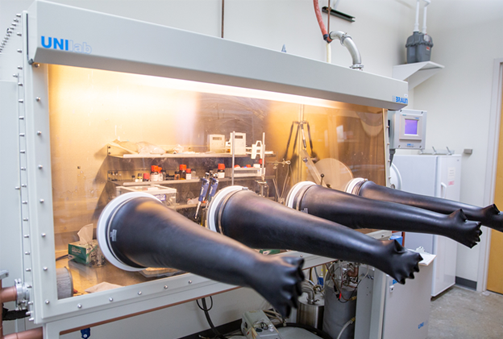

- NIOSH guidance notes that engineering control systems, such as adequate ventilation or scrubbing of contaminants, are the preferred control methods for reducing potential exposures. A primary engineering control used in the nanotechnology industry during the handling, weighing, mixing, or sonication of engineered nanomaterials is a ventilated enclosure. NIOSH recommends the use of local exhaust ventilation (e.g., laboratory chemical fume hoods; Figure 2). Exhaust air should be passed through a high-efficiency particulate air (HEPA) filter and, when feasible, released outside the facility. If the exhaust air is recirculated, then steps should be taken to ensure that recirculated air does not contain the nanoparticles (see NIOSH’s General Safe Practices for Working with Engineered Nanomaterials in Research Laboratories). Other engineering controls for safe handling include nanomaterial handling enclosures (glove boxes or isolators; Figure 3) and biological safety cabinets. Additional details are available in NIOSH’s Controlling Health Hazards When Working with Nanomaterials: Questions to Ask Before You Start.

- Laboratory equipment and exhaust systems should also be evaluated for any nanomaterial contamination before removal, remodeling, or repair.

- Equipment that was previously used to manufacture or handle nanoparticles should also be evaluated for any nanomaterial contamination before disposal or reuse.

Administrative Controls

- Administrative controls, such as appropriate signs and labels, access control, and a chemical hygiene plan including standard operating procedures (SOPs) and hazard assessment, are important aspects of good laboratory practices and are part of a hierarchy of controls supporting the implementation of feasible and effective control solutions.

- Housekeeping is an important aspect to prevent any exposures to nanomaterials. The work area and equipment should be cleaned regularly to avoid any exposure. Immediately clean spills involving nanomaterials according to written protocols or SOPs and using proper personal protective equipment. Typical methods for cleaning spills can be used for cleaning surfaces contaminated with dry powder nanomaterials. Never use flammable solvents for cleaning nanomaterials with flammable or pyrophoric properties. Clean dry nanomaterials with damp cloths, or by wetting the powder before wiping. Avoid using compressed air or other high-energy techniques, such as brushing or shaking, to remove nanomaterials from clothing.

- Test vacuum cleaners used to clean up nanoparticles; use HEPA-filtered units. Personal protective equipment should be used during spill cleanups and equipment maintenance.

- Dispose of and transport waste nanoparticles according to hazardous chemical waste guidelines, such as EPA’s Managing Laboratory Hazardous Waste guidance document.

Personal Protective Equipment

- Use good general laboratory safety practices as found in your organization’s chemical hygiene plan. Wear personal protective equipment (nitrile or chemical-resistant gloves, lab coats, safety glasses, face shields, and closed-toed shoes) as needed. Avoid skin contact with nanoparticles or nanoparticle-containing solutions by using appropriate personal protective equipment. The NIOSH Personal Protective Technology Program has the most up-to-date information on appropriate personal protective technologies for workforce safety. See also NIOSH’s General Safe Practices for Working with Engineered Nanomaterials in Research Laboratories.

- Respirators should be used only when engineering control systems are not feasible or where engineering controls alone may not be considered adequate to completely prevent exposure (see NIOSH’s General Safe Practices for Working with Engineered Nanomaterials in Research Laboratories). If it is necessary to handle nanoparticle powders outside of a HEPA-filtered powered-exhaust laminar flow hood, wear appropriate respiratory protection. The appropriate respirator should be selected on the basis of professional consultation, should meet NIOSH certification requirements, and should follow OSHA standards on respiratory protective equipment (Personal Protective Equipment, Standard 1910.134).

Training and Education

- Students and researchers should be provided with safety training and education to understand the nature of possible workplace exposures, health risks, routes of exposure, and instructions for reporting health symptoms, including proper use of engineering controls and maintenance of control. See below for training resources as well as NIOSH’s Protecting Workers During Nanomaterial Reactor Operations.

Preparing for Emergencies

Preparedness and response for nanomateral emergencies should follow the laboratory’s overall emergency planning. Start by reviewing the response to fires, spills and releases, and consider what additional steps might be appropriate based on this guidance. In particular, significant exposures or symptoms of a possible exposure should be reviewed by a medical professional, preferably an occupational health specialist.

Nanotechnology Safety Publications, Videos & Other Resources

Key Publications

- National Nanotechnology Initiative. Resources for Nanotechnology Laboratory Safety.

- NIOSH. 2018. Workplace Design Solutions: Protecting Workers during the Handling of Nanomaterials.

- NIOSH. 2018. Workplace Design Solutions: Protecting Workers during Nanomaterial Reactor Operations.

- NIOSH. 2018. Controlling Health Hazards When Working with Nanomaterials: Questions to Ask Before You Start. [PDF]

- NIOSH. 2012. General Safe Practices for Working with Engineered Nanomaterials in Research Laboratories. DHHS (NIOSH) Publication No. 2012-147.

- NIOSH. 2009. Approaches to Safe Nanotechnology: Managing the Health and Safety Concerns Associated with Engineered Nanomaterials.

- National Nanotechnology Initiative (NNI). Resources for Nanotechnology Laboratory Safety.

- OSHA. Working Safely with Nanomaterials. [PDF]

Videos & Webinars

- ACS. Working Safely with Nanomaterials in the Laboratory. [Video]

- NNI. NanoEHS Webinar: Applying a Lab Safety Culture to Nanotechnology: Educating the Next Generation of Nanoscientists, May 18, 2016 - Video with Closed Captioning. [Webinar]

- NIOSH. Nano Research: Engineering Controls for Nanomaterial Production and Handling Processes. [YouTube Video]

Other Nanotechnology Safety Resources

- American Industrial Hygiene Association. 2018. Personal Protective Equipment for Engineered Nanoparticles Fact Sheet. American Industrial Hygiene Association Nanotechnology Working Group. [PDF]ACS. 2015. Identifying and Evaluating Hazards in Research Laboratories. [PDF]

- NIOSH, Oregon Nanoscience and Microtechnologies Institute, Oregon State University. 2013. The GoodNanoGuide. Hosted by NanoHUB.

- California Nanosafety Consortium of Higher Education. 2012. Nanotoolkit: Working Safely with Engineered Nanomaterials in Academic Research Settings. [PDF]

- National Nanotechnology Coordinated Infrastructure

- American National Standards Institute, Nanotechnology Standards

References

- National Nanotechnology Initiative. National Nanotechnology Initiative (NNI) Supplement to the President’s 2020 Budget. 2019. https://www.nano.gov/2019BudgetSupplement.

- Oberdörster, G.; Oberdörster, E.; Oberdörster, J. Nanotoxicology: An Emerging Discipline Evolving from Studies of Ultrafine Particles. Environ. Health Perspect. 2005, 113 (7), 823–839. https://doi.org/10.1289/ehp.7339.

- Schulte, P. A.; Leso, V.; Niang, M.; Iavicoli, I. Current State of Knowledge on the Health Effects of Engineered Nanomaterials in Workers: A Systematic Review of Human Studies and Epidemiological Investigations. Scand. J. Work. Environ. Health 2019, 45 (3), 217—238. https://doi.org/10.5271/sjweh.3800.

- Warheit, D. B. Hazard and Risk Assessment Strategies for Nanoparticle Exposures: How Far Have We Come in the Past 10 Years? F1000Research 2018, 7, 376–376. https://doi.org/10.12688/f1000research.12691.1.

- Warheit, D. B.; Sayes, C. M. Chapter 1.2 - Routes of Exposure to Nanoparticles: Hazard Tests Related to Portal Entries. In Nanoengineering, Dolez, P. I., Ed.; Elsevier: Amsterdam, 2015, 41–54. https://doi.org/10.1016/B978-0-444-62747-6.00002-6.

- Schulte, P.; Roth, G.; Hodson, L.; Murashov, V.; Hoover, M.; Zumwalde, R.; Kuempel, E. D.; Geraci, C. L.; Stefaniak, A.; Castranova, V.; et al. Taking Stock of the Occupational Safety and Health Challenges of Nanotechnology: 2000–2015. J. Nanoparticle Res. 2016, 18. https://doi.org/10.1007/s11051-016-3459-1.

- Warheit, D. B.; Sayes, C. M.; Reed, K. L.; Swain, K. A. Health Effects Related to Nanoparticle Exposures: Environmental, Health and Safety Considerations for Assessing Hazards and Risks. Pharmacol. Ther. 2008, 120 (1), 35–42. https://doi.org/10.1016/j.pharmthera.2008.07.001.

- Schubauer-Berigan, M. K.; Dahm, M. M.; Schulte, P. A.; Hodson, L.; Geraci, C. L. Characterizing Adoption of Precautionary Risk Management Guidance for Nanomaterials, an Emerging Occupational Hazard. J. Occup. Environ. Hyg. 2015, 12 (1), 69–75. https://doi.org/10.1080/15459624.2014.946515.

Last updated 2021-09-02, American Chemical Society Committee on Chemical Safety